SMRT renews ageing track foundations to improve reliability on North-South, East-West lines

Sign up now: Get ST's newsletters delivered to your inbox

Follow topic:

- Ageing ballast on NSEWL needs renewal after 38 years due to wear. SMRT is doing localised replacements.

- Renewing ballast is labour-intensive, done manually within limited nightly hours. SMRT explores extended hours and new technologies.

- SMRT monitors ballast degradation and plans a larger renewal programme to enhance rail infrastructure, ensuring long-term reliability.

AI generated

SINGAPORE – Efforts are under way to renew the ballast foundations of the North-South and East-West MRT lines (NSEWL), as the ageing stones beneath the tracks show signs of wear after nearly four decades of service.

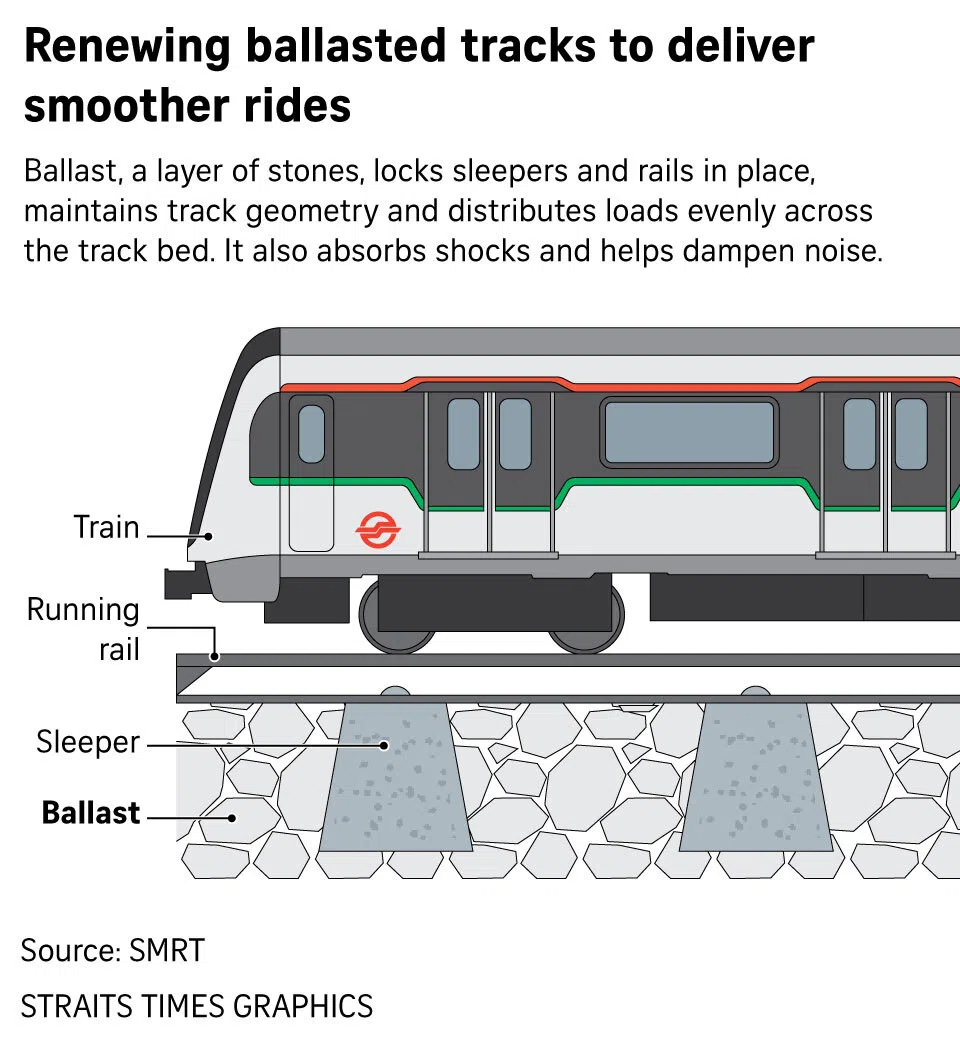

Ballast, a layer of hard, angular stones, such as granite or basalt, forms the foundation of ballasted tracks.

The stones interlock tightly to hold sleepers and rails in place, keep track geometry stable under fast and frequent train movements and distribute loads evenly across the track bed.

They also absorb shocks and vibrations, reduce wear on rails and wheels and help dampen noise.

Because ballast drains water efficiently and withstands repeated compression, it provides a durable base that is central to safe and reliable train operations.

But after 38 years, the edges of ballast stones on parts of the NSEWL have become rounded and crushed under heavy train loading and exposure to the elements.

The lines, which began operations in 1987, are the only ones in Singapore that operate on a ballasted track.

SMRT demonstrated ballast renewal works during an overnight media visit to Bishan MRT station on the NSL on Dec 11.

Stretches of the rail now require renewal or replacement to maintain track stability and prevent deterioration that could affect ride quality or reliability.

Renewing ballast is labour-intensive. It takes 10 to 12 workers roughly three hours to replace the stones on an up to 5m stretch of the track.

Together, the two lines have a track length of 205km, of which 146km – or 71 per cent – is above ground and ballasted. The remaining 59km of line is mainly located underground and has concrete slab foundations. One exception is the 7.5km-long Tuas West Extension of the EWL, which is above ground and built on concrete slab foundations.

In the short to medium term, SMRT will carry out localised renewals whenever its monitoring regime detects early signs of degradation. In 2025, it has completed seven short stretches of about 4m to 5m each on the NSEWL, Singapore’s oldest rail lines.

All replacement work is currently done manually, as deploying large maintenance machines would consume too much of the nightly engineering window, which lasts just 3.5 to 4 hours.

The operator is exploring extended maintenance hours to support a larger-scale renewal programme. Longer work windows would allow the use of specialised machines that can speed up and expand renewal efforts.

SMRT collects ballast samples from across the NSEWL every three years and sends them for laboratory testing to determine the level of degradation and identify areas of the tracks to prioritise for renewal.

Recent results show a growing number of locations requiring renewal, prompting pre-emptive plans to expand the programme to safeguard long-term reliability.

How ballast renewal works

A team begins by digging out the old stones between two sleepers – which are about 70cm apart and have a depth of about 50cm – using spades. This extraction process takes 45 minutes to an hour.

A team of 10 to 12 staff members work on digging up the old ballast in between sleepers during the ballast renewal process at Bishan MRT station in the early hours of Dec 11.

ST PHOTO: MARK CHEONG

Fresh ballast is then poured in, taking 20 to 30 minutes. About 150 bags of stone, each weighing 15kg, are needed to fill the space, roughly 2,250kg in total.

Old (left) and new (right) ballasts are seen in this side-by-side comparison during ballast renewal works at Bishan MRT station in the early hours of Dec 11.

ST PHOTO: MARK CHEONG

Each sleeper weighs 300kg, and the rails above them weigh 60kg per metre. The ballast bed beneath must support the weight, as well as train loads, while locking the sleepers and rails firmly in position.

New ballasts (left) and old ballasts are seen in between sleepers during the renewal process at Bishan MRT station in the early hours of Dec 11.

ST PHOTO: MARK CHEONG

The final step is compaction. Workers use tamping machines to press the stones beneath and around the sleepers into a uniform bed. This takes up to 20 minutes and is crucial for restoring track geometry and ensuring stable, smooth train operations.

Staff are seen using a specialised tamping machine to compact the ballast beneath and around the sleepers at Bishan MRT station in the early hours of Dec 11. This is to ensure proper alignment and even distribution.

ST PHOTO: MARK CHEONG

An engineer then uses a handheld track gauge to make sure the rails on which the train runs are aligned and the ballast foundation is stable.

Ballast stones can last up to 50 years, but their lifespan depends heavily on train frequency, passenger loads and weather exposure. In Singapore, where train intervals can be as short as 2½ minutes and ridership is high, stones degrade more quickly.

Slab track is preferred in tunnels, where noise and drainage are less of a concern, and requires less maintenance.

Ballasted track, however, performs better in the open, where it absorbs vibration, manages water run-off and reduces noise.

The train tracks at Bishan MRT station in the early hours of Dec 11.

ST PHOTO: MARK CHEONG

Maintenance demands are expected to rise as ballast renewal ramps up, owing to the sheer weight and volume of stones involved. With only about three to four hours of nightly engineering time, scaling up the work remains a challenge.

Trackside equipment such as the third rail supplying power to trains and signalling systems also limits the type of machinery that can be used.

This means much of the work must still be done manually and carefully around systems, such as point machines that direct trains onto different tracks and signalling components.

“Ballast may look like simple stones, but it plays a critical role in rail reliability,” said Mr Brandon Joshua Fong, executive engineer at SMRT.

The task of renewing ballast is complex and work must be carried out carefully, Mr Fong said.

He said SMRT has begun targeted replacement works and is exploring newer renewal technologies, without elaborating.

“We look forward to a scaled-up ballast renewal programme in the near future, to further enhance and strengthen the resilience of our rail infrastructure,” said Mr Fong.