Largest industrial district cooling system begins operations in Ang Mo Kio

Sign up now: Get ST's newsletters delivered to your inbox

Senior Minister of State for Trade and Industry Low Yen Ling (in pink) touring the cooling plant at Ang Mo Kio TechnoPark on Oct 21.

ST PHOTO: GIN TAY

- Singapore launched its largest industrial district cooling network in Ang Mo Kio, supplying STMicroelectronics, cutting cooling electricity use by 20%.

- The system will cut carbon emissions by up to 120,000 tonnes yearly, freeing 4,000 sq m for PFC abatement equipment.

- SP Group is upgrading STMicroelectronics' Toa Payoh cooling system; aiming for completion by 2025 and reducing emissions by 2,140 tonnes annually.

AI generated

SINGAPORE – Singapore’s largest industrial district cooling network by capacity was launched in Ang Mo Kio on Oct 21.

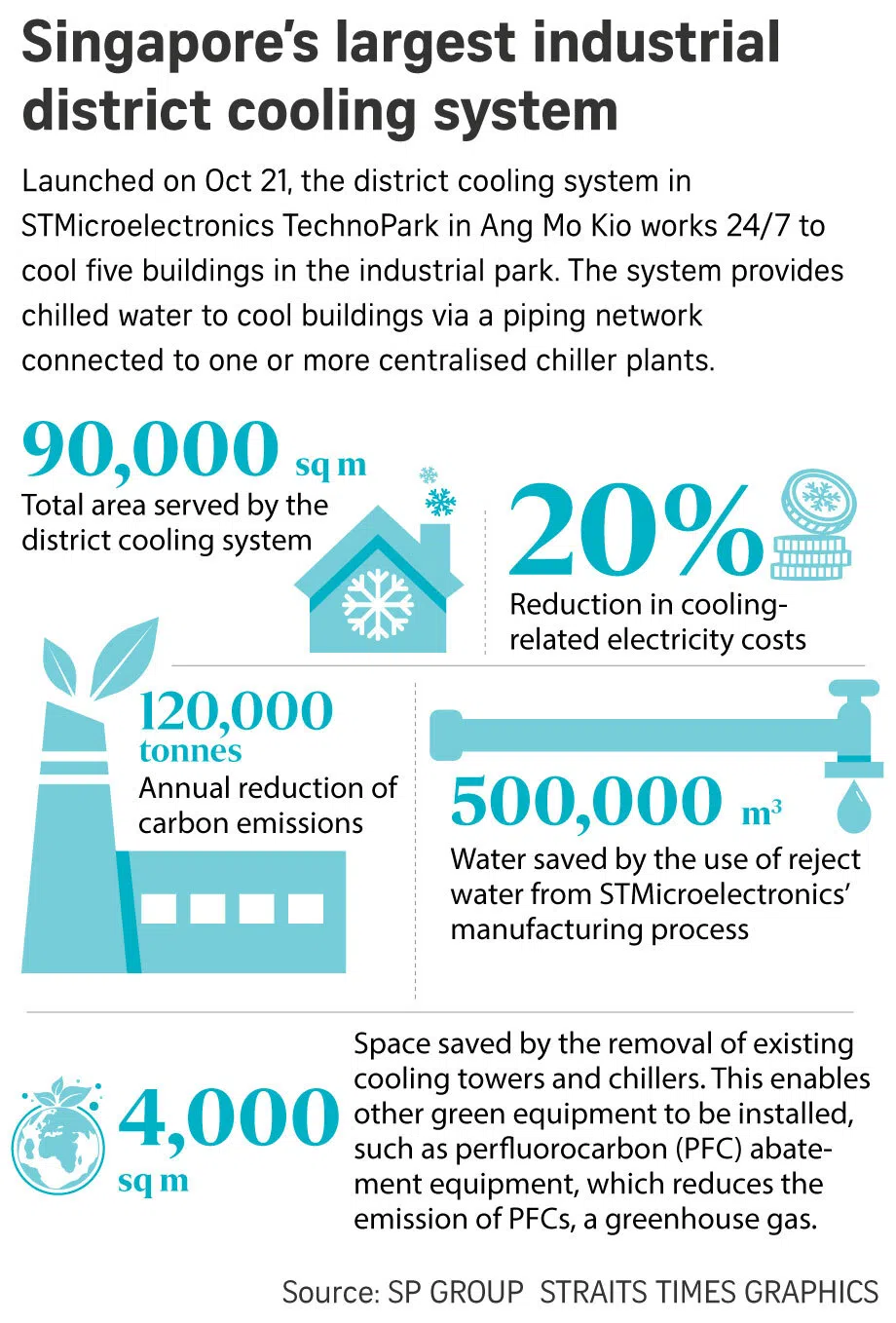

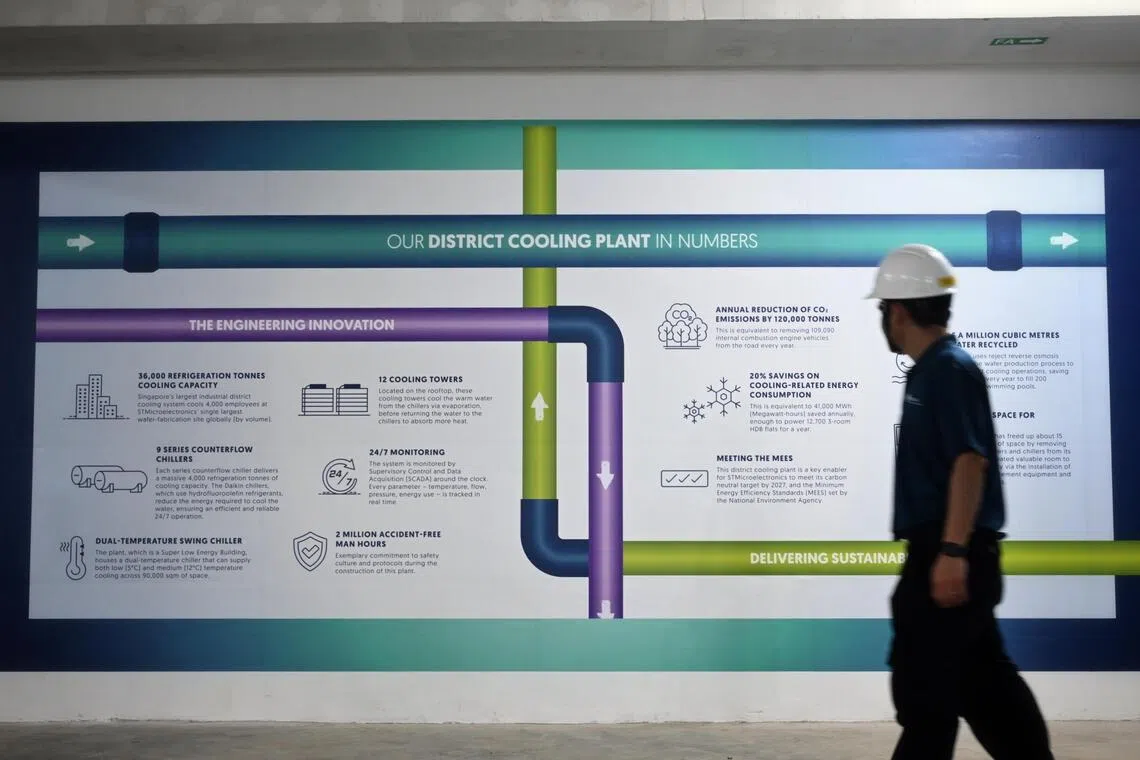

It will cut cooling-related electricity consumption by 20 per cent, save over 500,000 cubic metres of water each year, and help reduce up to 120,000 tonnes of carbon emissions annually.

Covering a total area of 90,000 sq m, the centralised cooling network will supply chilled water to five buildings owned by global semiconductor manufacturer STMicroelectronics in a technopark in Ang Mo Kio.

Other industrial areas with district cooling systems include Woodlands Wafer Fab Park, Jurong Innovation District and Changi Business Park, all operated by Keppel DHCS.

District cooling systems have also been rolled out in the civic district and residential areas, such as Marina Bay and Tampines.

A district cooling system provides chilled water to cool buildings, which are connected by a piping network to one or more centralised chiller plants. This helps to cut carbon emissions, save energy and enhance efficiency through economies of scale.

Besides cutting electricity consumption, the estimated decarbonisation stems from repurposing about 4,000 sq m of space across the five buildings previously occupied by chiller plants.

This will provide space to install equipment to reduce perfluorocarbon (PFC) emissions produced from manufacturing semiconductors that are harmful to the environment.

The district cooling system will help to cut carbon emissions by up to 120,000 tonnes a year, equivalent to removing 110,000 cars from the roads a year.

Speaking at the launch on Oct 21, Senior Minister of State for Trade and Industry Low Yen Ling said the new district cooling system could serve as a blueprint for innovative design and deployment of district cooling for businesses here.

Companies should consider not just deploying district cooling systems for their cooling needs, but also integrating them with other sustainable energy solutions such as solar energy and EV charging.

“By integrating all these energy-efficiency solutions, it will certainly enable further carbon emissions reduction as well as energy efficiency improvements,” she said.

She added that the Government will support businesses in their decarbonisation and energy efficiency efforts, pointing to schemes such as the Resource Efficiency Grant for Emissions, which provides funding for eligible emissions reduction projects.

STMicroelectronics’ district cooling system is a $513 million project designed, built, owned and operated by a joint venture between utilities company SP Group and Daikin Airconditioning.

Built in Daikin Airconditioning Singapore’s main facility in Ang Mo Kio, it has a cooling capacity of 36,000 refrigeration tonnes.

The district cooling system will help to cut carbon emissions by up to 120,000 tonnes a year.

ST PHOTO: CHONG JUN LIANG

The system will also save over 500,000 cubic metres of water each year, using reverse osmosis to repurpose reject water from STMicroelectronics’ manufacturing process for the chilling operations. Reverse osmosis is a purification process that removes contaminants from water.

One challenge when building the system was ensuring that there was no interruption to STMicroelectronics’ operations, said SP Group sustainable energy solutions managing director S. Harsha.

“We had to think about how we were going to pipe and chill water into the existing facilities without having to disrupt their operations at any point in time,” he said, noting this required close cooperation with STMicroelectronics.

The pipes that transport chilled water to cool the industrial park and receive the warm water from the industrial park.

ST PHOTO: CHONG JUN LIANG

Formed after a merger between Italian microelectronics firm SGS Group and the semiconductor arm of French electronics firm Thomson, STMicroelectronics has had a presence in Singapore since 1969.

STMicroelectronics group vice-president Eugene Lee said the multinational company also has other sustainability efforts, such as working with other companies to repurpose wastewater sludge into building materials, and recycling used plastics into pavements.

Mr Lee, who is also STMicroelectronics’ general manager for front-end manufacturing Asia operations, noted that the firm is on track to meet its goal of becoming carbon neutral by 2027.

STMicroelectronics is currently upgrading the cooling system at its Toa Payoh site. SP Group is designing and building a new high-efficiency chiller, which it will also operate when the system is completed by December. It is estimated that the new system in Toa Payoh could reduce carbon emissions by 2,140 tonnes a year.

Singapore manufactures one in 10 chips and one-fifth of global semiconductor equipment, with the sector here attracting more than $18 billion worth of research and development, as well as manufacturing investments, in the past two years, according to the Economic Development Board.

Other companies producing semiconductor chips here include GlobalFoundries, UMC and Micron.