NUS breakthrough a boost for more durable, comfortable healthcare equipment

Sign up now: Get ST's newsletters delivered to your inbox

Dr Chen Shuwen, one of the researchers from NUS, with a prototype of the Bilayer Liquid-Solid Conductor.

PHOTO: NUS

SINGAPORE – Scientists in Singapore have developed an electricity-conducting circuit that stretches up to 22 times its original length and heals itself when it tears, paving the way for more durable and comfortable healthcare and monitoring equipment that can be mounted on or wrapped around a patient’s body.

Developed by the National University of Singapore (NUS), the breakthrough aims to break free from the rigid designs of circuits that power smart devices today.

These circuits are usually made of conductive metals that are stiff or prone to damage.

Researchers from NUS developed a material called Bilayer Liquid-Solid Conductor that can stretch up to 22 times its original length without a significant drop in electrical conductivity, said Professor Lim Chwee Teck, director of the Institute for Health Innovation and Technology at NUS and head of the research team.

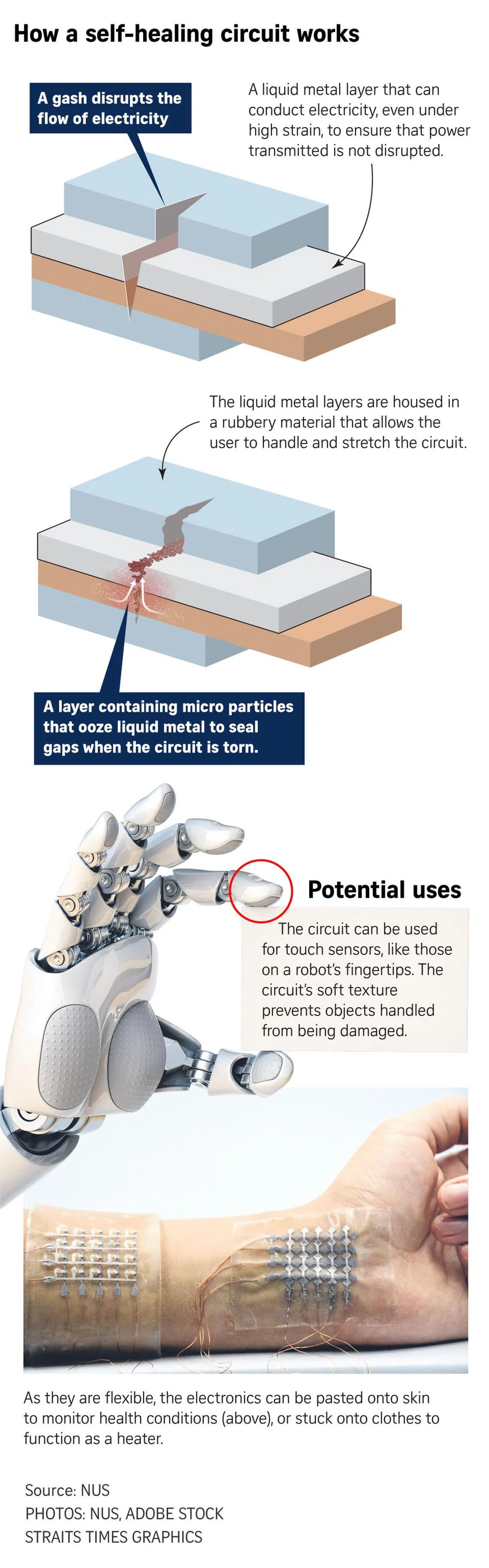

The circuit comprises two layers. The first is a pure liquid metal layer that can conduct enough electricity, even under high strain, to ensure that the power and signal transmitted are not disrupted.

The second layer consists of liquid metal micro particles that ooze out to seal gaps when the circuit is torn.

The two layers are housed in a 3D-printed rubbery material that allows the user to stretch the circuit and wrap it around objects.

“When a crack or tear occurs, the liquid metal flowing out from the micro particles can flow into the gap, allowing the material to heal itself almost instantaneously to retain its high conductivity,” Prof Lim said. This can help to improve the durability of wearable electronics and reduce waste in the long run, he noted.

“We are looking at rehabilitation involving large movement and bending such as the knee and elbow,” he added.

“Most wearables for such physiotherapy involve multiple components that are loosely attached to the side of the knee... What we aim to do with our wearable device is that it can directly be attached to the knee and measure directly the flexing of the knee, with an LED display to show if the flexing is done correctly or the knee has undergone sufficient flexing.”

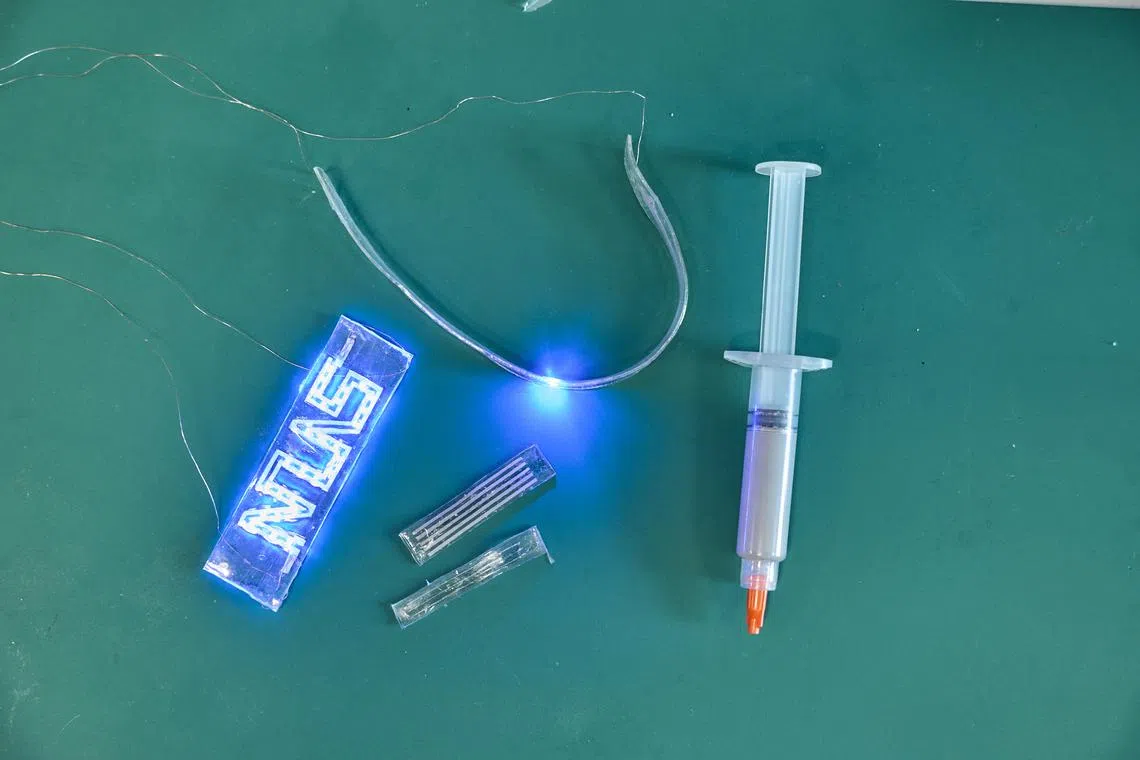

The team members have used the circuit to create electronic devices such as wearable heaters, light strips and antennas for wireless communication. They are seeking partnerships with potential users of the technology, such as for patients undergoing rehabilitation or gymgoers.

The NUS team has used the circuit to create electronic devices such as wearable heaters, light strips, and antennas for wireless communication.

PHOTO: NUS

The circuit opens up new opportunities for use in healthcare wearables, soft robotics and other smart devices, said Prof Lim. For instance, pressure sensors made from these circuits can be wrapped around the fingertips of a robot to give the machine a sense of touch, while its soft texture prevents damage to the item.

His team joins other innovators in the race to create self-healing electronics, including scientists at Stanford University in the US, who are also looking into materials for robotics and wearables.

Professor Lim Chwee Teck and Dr Chen Shuwen (right), one of the team members, holding a prototype of the Bilayer Liquid-Solid Conductor.

PHOTO: NUS

Dr Ong Poo Lee from Tan Tock Seng Hospital, who specialises in rehabilitation medicine, said that while wearables are not widely used during treatment yet, the technology could yield new possibilities.

The hospital is in its early phases of adopting wearables that are sometimes used to treat patients who are recovering from stroke, brain injuries or amputations, added Dr Ong, noting that ease of use is a key consideration.