New lab at NTU to advance AI-powered humanoid robots for industry use

Sign up now: Get ST's newsletters delivered to your inbox

(From left) Schaeffler (Singapore) regional CEO Asia-Pacific and managing director Maximilian Fiedler, NTU vice-president (industry) Lam Khin Yong and Schaeffler chief technology officer Uwe Wagner, at the launch of Schaeffler-NTU Corporate Lab: Intelligent Mechatronics Hub at the Wee Cho Yaw Plaza on Nov 27.

ST PHOTO: SHINTARO TAY

- NTU and Schaeffler launched a corporate lab focused on AI-enabled humanoid robotics for manufacturing, logistics and healthcare.

- The lab aims to improve humanoid robot actuators, which are similar to human joints, by making them smaller, lighter, more energy-efficient and cost-effective.

- The collaboration supports talent development and will boost Singapore's robotics capabilities.

AI generated

SINGAPORE – A new corporate laboratory for further research and innovation in artificial intelligence (AI)-enabled humanoid robotics was officially launched at the Nanyang Technological University (NTU) on Nov 27.

Humanoid robots are designed to resemble the human form and built to mimic human motion and behaviour. They have been touted as the next big development in tech, with companies looking to deploy them on manufacturing floors and logistics hubs for a start.

The new lab is part of the third phase of collaboration between NTU and automotive and industrial components supplier Schaeffler, which began in 2017.

Called the Schaeffler-NTU Corporate Lab: Intelligent Mechatronics Hub, the new 900 sq m facility will focus on humanoid robot applications in manufacturing, logistics and healthcare.

Funding for the new lab comes under a $70 million joint funding arrangement from the National Research Foundation, Singapore, under the Research, Innovation and Enterprise 2025 Plan. The funding covers NTU and Schaeffler’s collaboration efforts from 2017 to 2029.

Speaking to The Straits Times on the sidelines of the launch event on Nov 27, Schaeffler chief technology officer Uwe Wagner said the new lab will look into making humanoid components called actuators that are smaller, lighter, more energy-efficient and cost-effective.

Actuators, which are the equivalent of human joints and muscles, help robots make human-like movements.

“If we can improve the energy efficiency of the actuation system by 10 per cent or 20 per cent, it could extend the operation time by 20 per cent,” said Mr Wagner, adding that actuators take up more than 50 per cent of the cost of a humanoid robot.

The new lab will also study the cost-effectiveness and feasibility of integrating humanoids for industrial applications such as on production lines for manufacturing and logistics, where they could take over repetitive and monotonous tasks.

Previous collaboration efforts between NTU and Schaeffler covered research and development in smart mobility devices, automation and machine learning. One of the key prototypes produced was a humanoid robot called LINH.

LINH has the ability to understand and respond to verbal commands in multiple languages, use both arms to manipulate objects and process and recognise objects in real time. With the new lab, the focus will be on replicating and improving LINH’s abilities for humanoid robot development.

Beyond research, the partnership also supports talent development by training PhD, master’s and undergraduate students, providing them with hands-on experience through working alongside Schaeffler engineers and researchers on real-world projects. About 100 students and researchers have benefited from the collaboration.

Professor Lam Khin Yong, NTU vice-president (industry), said NTU has worked closely with Schaeffler engineers to develop robots that can work alongside humans, with advanced sensors improving sensitivity and safety, which have a direct industrial impact.

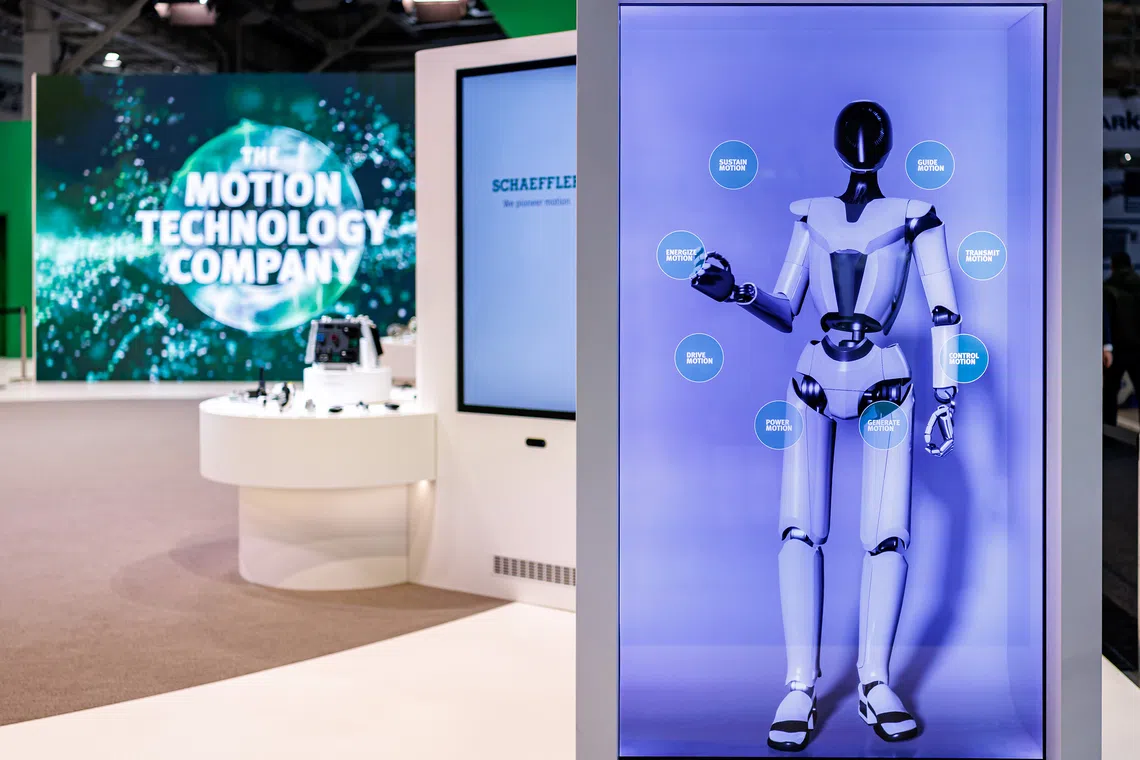

The Schaeffler Humanoid demonstrator on display at the Hannover Fair 2025 in Germany. The demonstrator provides a glimpse into Schaeffler’s key components and sub-systems that enable motion in humanoid robots.

PHOTO: SCHAEFFLER

“I’m confident that our innovations can boost the manufacturing sector and shape the future of autonomous and assistive robotics in Singapore and beyond,” he said.

At the launch event, Minister-in-charge of Energy and Science and Technology Tan See Leng said that in 2023, Singapore ranked second globally in robot density, with 770 robots per 10,000 employees.

“This clearly reflects the increasing need for robotics to augment workforce productivity across industries,” said Dr Tan, who is also Manpower Minister.

“The Schaeffler-NTU collaboration aligns with Singapore’s goals to develop differentiated robotics capabilities, complementing the efforts of our advanced manufacturing companies by enhancing automation, precision and productivity.”