Tuas Newater Factory to increase production capacity to 75 million gallons a day

Sign up now: Get ST's newsletters delivered to your inbox

SINGAPORE – Singapore is ramping up its production of Newater by 50 million gallons a day with the expansion of the upcoming Tuas Newater Factory, as it anticipates an increase in demand for water in the future.

National water agency PUB announced on Sept 27 that it will launch a construction tender for the expansion, which will increase the factory’s initial production capacity of 25 million gallons a day to 75 million gallons a day.

Singapore’s water demand is expected to almost double by 2065, so Newater’s role as a reliable and weather-resilient national tap remains crucial, said Minister for Sustainability and the Environment Grace Fu.

Singapore uses about 440 million gallons of water a day. Newater could meet up to 40 per cent of the nation’s water needs, according to PUB in 2018.

Singapore’s other sources of water are desalination plants, imported water from Malaysia (up to 250 million gallons a day), and water from local catchments.

The Tuas Newater Factory will be integrated with the Tuas Water Reclamation Plant, which is currently under construction and expected to be operational in 2026, as reported in September 2023.

Its new capacity of 75 million gallons a day is equivalent to 136 Olympic-size swimming pools.

PUB is currently transitioning to a new used water management system, where used water will be sent to three water reclamation plants in the northern, western and eastern regions in Singapore via the Deep Tunnel Sewerage System –

Five Newater factories will eventually be consolidated at the water reclamation plant in Changi, the upcoming Tuas plant, and the redeveloped Kranji plant to be completed around 2035.

The expansion of Tuas Newater Factory’s production capacity was announced by Ms Fu at the closing ceremony of the Newater Visitor Centre and Bedok Newater Factory on Sept 27.

The Bedok factory – which was the first Newater factory in Singapore when it opened in 2003 – has been closed as it has reached the end of its operational lifespan.

With the closing of the Bedok factory, there are currently four Newater factories – two in Changi and one each in Kranji and Ulu Pandan.

Ms Fu paid tribute to the contributions of the pioneers of Newater in her speech.

“Their foresight and perseverance have strengthened Singapore’s water resilience. They have enabled us to meet the nation’s growing water demands and face the water challenges brought about by climate change, and to do so with confidence and optimism,” she said.

Minister for Sustainability and the Environment Grace Fu viewing bottles of Newater on display at the Newater Visitor Centre on Sept 27.

ST PHOTO: LIM YAOHUI

With the closing of the Newater Visitor Centre, visitors can go to the Sustainable Singapore Gallery at Marina Barrage to learn more about Singapore’s water story, which features Newater.

PUB said that it is working on developing a new exhibit on Newater at the Marina Barrage gallery and at a learning gallery located at the upcoming Tuas Nexus, which will be Singapore’s first integrated water and solid waste treatment facility.

For more than two decades, the Newater Visitor Centre in Bedok had welcomed the public to learn about the ultra-clean, high-grade reclaimed water.

The centre, which also opened in 2003, holds fond memories for many of Newater’s pioneers.

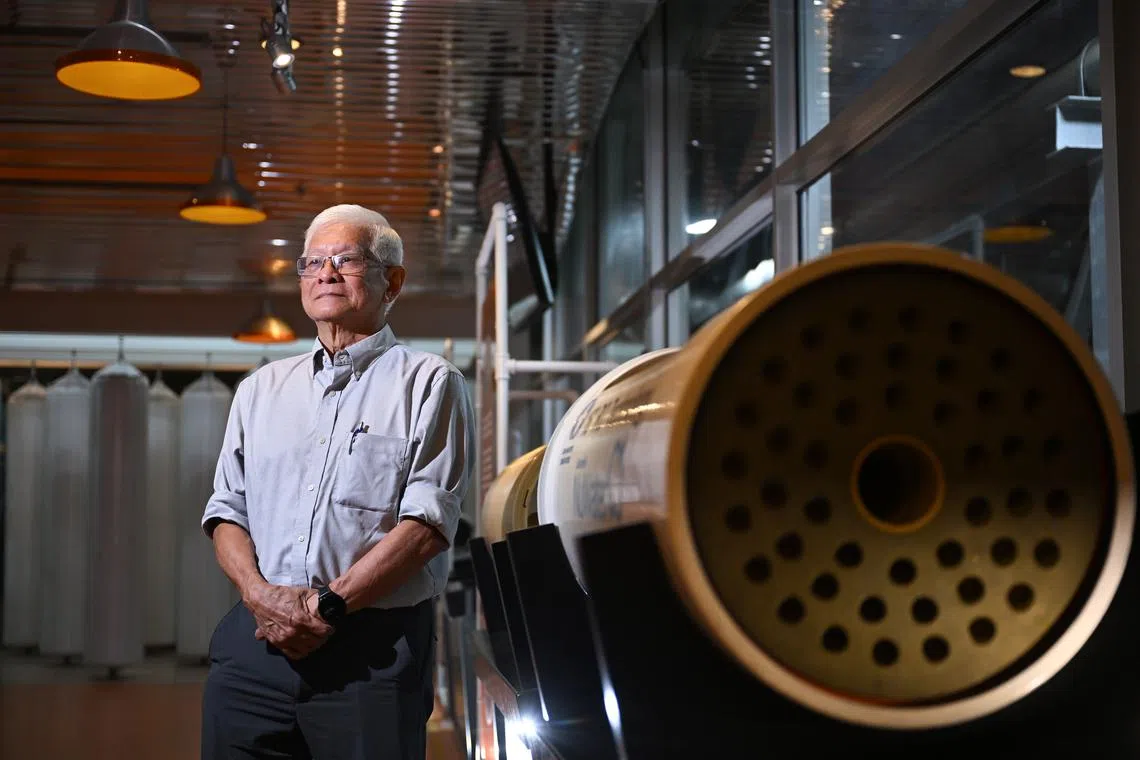

Professor Ong Choon Nam contributed technical knowledge as the chairman of the International Expert Panel on Newater from 1999 to 2003, along with his fellow panel members.

“The whole Newater story started with numerous experiments here... So this is actually the birthplace of Newater... And many of the exciting experiments and challenging issues were (solved) here,” he said, referring to the site before the centre and Bedok Newater Factory were built.

Professor Ong Choon Nam contributed technical knowledge as the chairman of the International Expert Panel on Newater from 1999 to 2003, along with his fellow panel members.

ST PHOTO: LIM YAOHUI

The 76-year-old was also the director of the Centre for Environmental and Occupational Health Research at the National University of Singapore, and led a team of researchers then to carry out more than 20,000 tests over 2½ years to evaluate the quality of Newater.

Before the Newater Visitor Centre and the Bedok Newater Factory were built, the Newater project team had to build a pilot plant to test out the reclaimed water.

Prof Ong, who is currently emeritus professor at NUS’ Saw Swee Hock School of Public Health, said that the team was overwhelmed when it saw the reclaimed water gushing out into a 3m-wide tub that was painted light blue.

“With the pristine water gushing out, you’d just feel like jumping in, as if it’s a jacuzzi,” Prof Ong added.

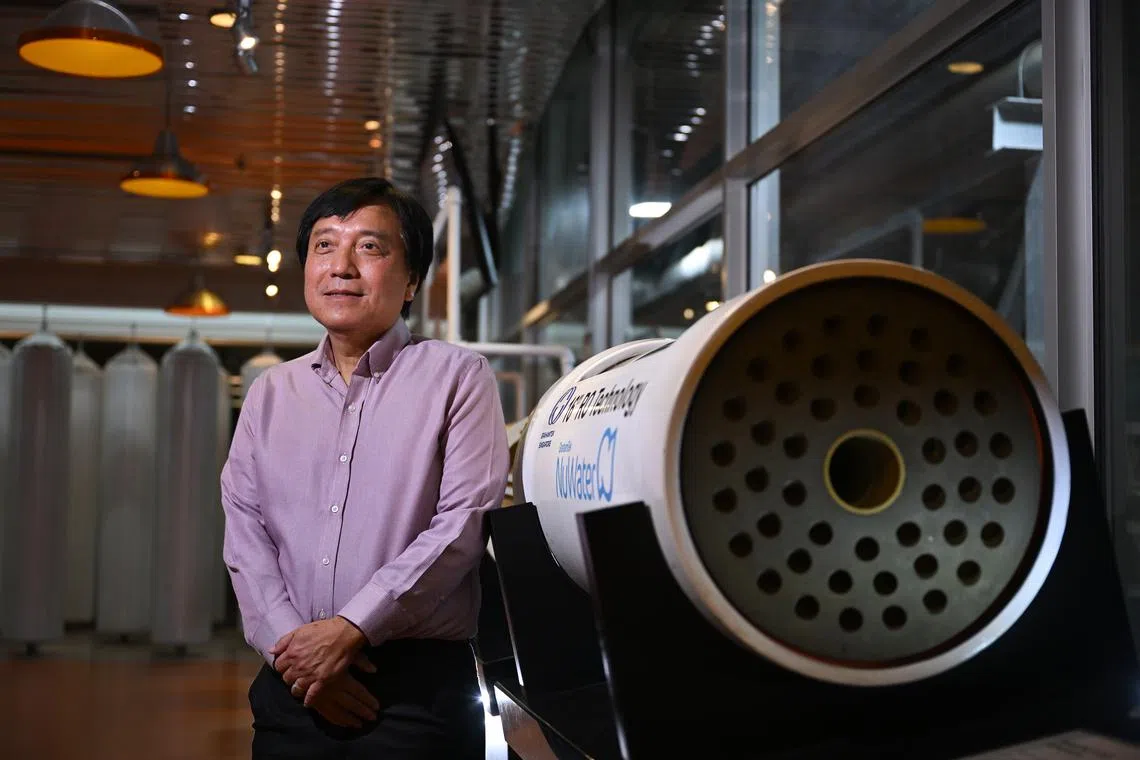

The Bedok Newater Factory was the office for Mr Tan Thai Pin, then the deputy project manager of the Newater study team, from 2000 to 2004.

The Bedok Newater Factory was the office for Mr Tan Thai Pin, then the deputy project manager of the Newater study team, from 2000 to 2004.

ST PHOTO: LIM YAOHUI

The 66-year-old played a crucial role in garnering support from industrial partners and convincing them to use Newater in their operations.

The reclaimed water has passed more than 150,000 scientific tests and is well within World Health Organisation guidelines for drinking water quality, and US Environmental Protection Agency drinking water standards.

It took Mr Tan and his team more than four months before semiconductor fabrication company Systems On Silicon Manufacturing became the first customer to support and adopt Newater in the wafer fabrication industry.

Mr Tan recalled that his job was tough, and he had to manage various stakeholders on top of other responsibilities.

“But it’s a job I had to do to make sure that the project actually succeeds and the water quality meets the standard 24/7 – every second, every drop of water. That’s the mission, as simple as that,” the retiree added.