Singapore’s biggest train and bus depot on course to open in 2026, 98% of structural works done

Sign up now: Get ST's newsletters delivered to your inbox

The East Coast Integrated Depot in Changi is on track to open in 2026.

ST PHOTO: JASON QUAH

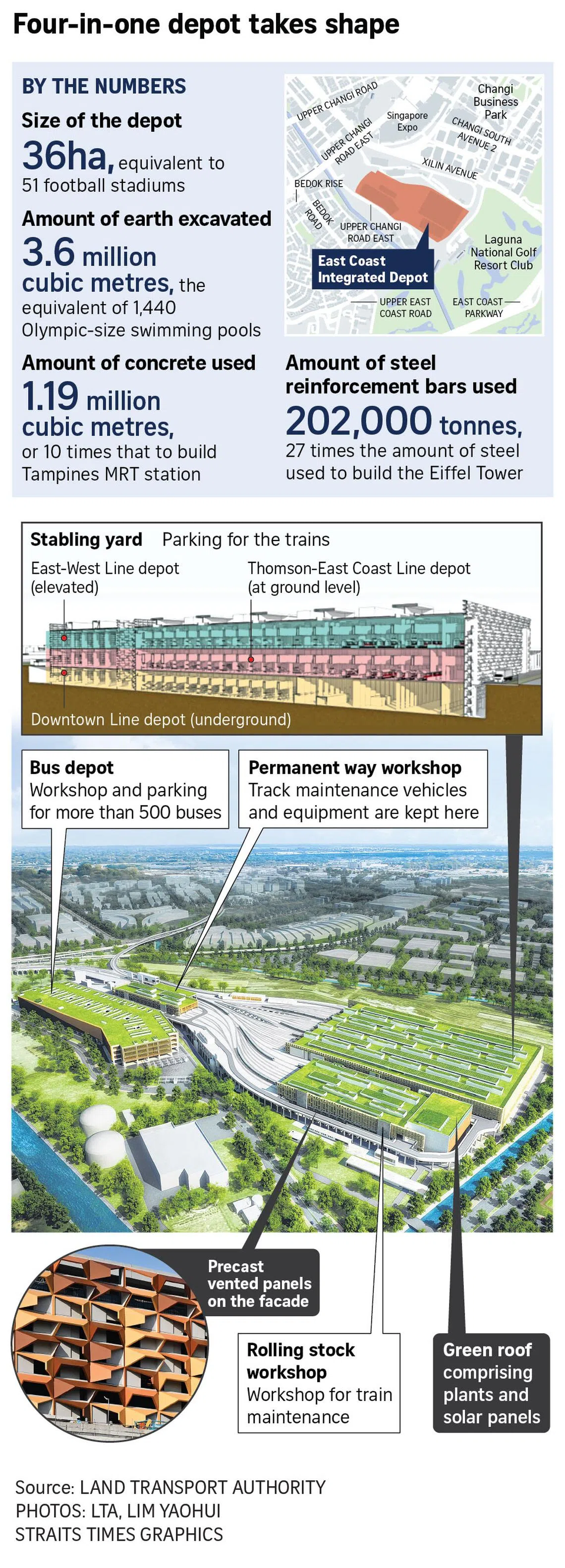

SINGAPORE – Structural and architectural works on Singapore’s largest train and bus depot are about 98 per cent completed, while works in other areas such as plumbing, electrical and other systems are 83 per cent done.

The East Coast Integrated Depot in Changi is on track to open in 2026, said the Land Transport Authority (LTA). Its original 2024 opening was pushed back twice, first to 2025

The remaining construction works include the fitting of rail tracks, architectural finishes, roadworks, and the installation of perimeter walls and fences.

LTA provided this update during a media visit to the 36ha worksite on Nov 27, ahead of the suspension of train service

Construction on the four-in-one depot started in 2016. When ready in 2026, the facility will house train depots serving three rail lines as well as a bus depot.

LTA said there will be two more planned service adjustments over the next two years, affecting different segments of the EWL, to facilitate the depot’s construction.

The exact dates and details about how train services will be affected will be announced later, added the authority.

During the visit, LTA took reporters through some of the construction challenges and innovations used in building the depot.

To make it easier and safer to operate heavy machinery such as excavators and tipper trucks when working on soft or unstable ground, a system of large interlocking mats – known as a “Mega Mat” – was used to support the vehicles.

This could be put in place more quickly and easily than laying conventional steel decking, which entails substantial work and is time-consuming.

The construction project also required the use of numerous precast beams and planks.

An improved design that merged the planks and secondary beams – those that are not directly connected to columns – into a single element reduced the total number of precast components from more than 105,000 pieces to about 34,000 pieces.

To reduce noise when the depot is in operation, the columns and ceiling of the bus depot are clad in sound-absorbing fibreboard panels.

The columns and ceiling of the bus depot are clad in sound-absorbing fibreboard panels to reduce noise when the depot is in operation.

ST PHOTO: JASON QUAH

Consistent with recent LTA projects, the depot design incorporates some eco-friendly features.

These include having plants on the roof of both the rail and bus depot buildings. Besides helping to bring down indoor temperatures, the green roof system at the depot – spanning about 47,000 sq m – will remove around 84 tonnes of carbon dioxide from the atmosphere yearly, LTA said.

The green roof system at the depot – spanning about 47,000 sq m – will remove around 84 tonnes of carbon dioxide from the atmosphere yearly.

ST PHOTO: JASON QUAH

Elsewhere on the roof of the depot are more than 14,000 solar panels with a 6.2 megawatt-peak capacity. LTA estimates that the use of solar panels will reduce the facility’s carbon emissions by more than 3,900 tonnes a year.

More than 14,000 solar panels with a 6.2 megawatt-peak capacity are installed.

ST PHOTO: JASON QUAH

The depot complexes do not rely on mechanical cooling systems. Instead, they use design features such as vented panels on the facade of the facility to maximise natural ventilation.

Made from precast concrete, the distinctive yellow-and-orange panels are also laid out in a way that optimises natural lighting.

The multi-storey train depot can house up to 220 trains.

The three train depots are stacked atop one another, with the Downtown Line (DTL) depot underground, the one for the Thomson-East Coast Line (TEL) on ground level, and the EWL depot on the level above.

Although they share facilities and systems, the three train depots are designed to operate independently.

The rail depots will enter service in phases, starting with the EWL’s. LTA told The Straits Times that an estimated 700 workers will operate the EWL depot, while the labour needs for the other two lines, as well as the bus depot, are still being worked out.

The multi-storey train depot can house up to 220 trains.

ST PHOTO: JASON QUAH

When the EWL depot is operational, the existing Changi Depot next to the East Coast Integrated Depot will be decommissioned and demolished, and the land reinstated and returned to the state.

At present, DTL trains use the Gali Batu Depot in Woodlands, while TEL trains berth at the Mandai Depot.

Rail company SMRT operates the EWL and TEL, while fellow operator SBS Transit runs the DTL.

The multi-storey bus depot is beside the train depot complex within the same plot.

A workshop is on the ground level, and the upper floors house a parking area that can hold over 500 buses – fewer than the 760 parking spaces announced earlier.

Asked about this, LTA said the design was updated to make room for electric bus infrastructure, including the capacity to charge about 240 electric buses as well as fire safety systems.

It added that locating the three rail depots in a single site in this way saved 44ha of land – the equivalent of about 60 football fields.

Integrating the MRT depots also helped to save about $2 billion. Building the bus and rail depots in this manner, instead of having them as individual set-ups, lowered construction costs by an estimated 40 per cent, LTA said.