SMRT’s new welding machine helps join tracks more durably, cuts time for replacements

Sign up now: Get ST's newsletters delivered to your inbox

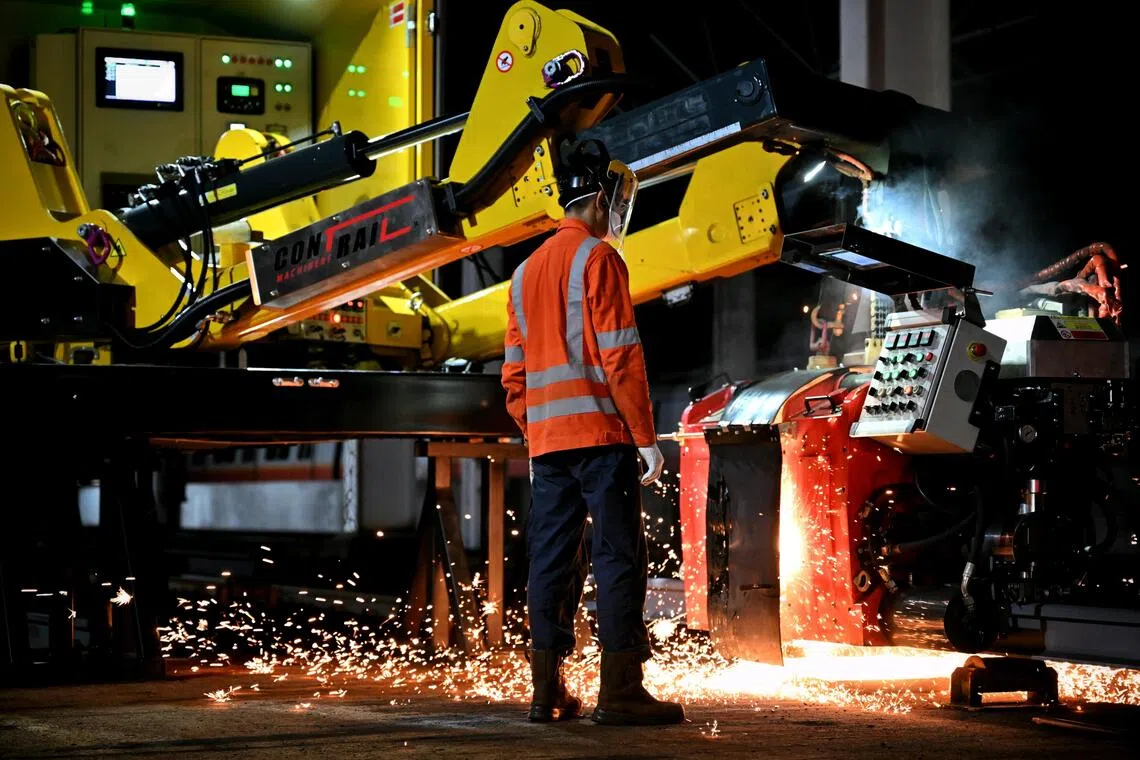

The flash butt welding machine can clamp down on and weld rail ends together to complete a rail replacement operation within 15 minutes.

ST PHOTO: ARIFFIN JAMAR

- SMRT acquired a $1 million flash butt welding machine in February, enhancing rail replacement efficiency by 20% and improving reliability.

- The machine welds rails in 15 minutes, reducing labour and improving weld durability without fillers, unlike manual welding that takes 40 minutes.

- By the first quarter of 2026, SMRT will use the modified machine directly on the tracks of the North-South and East-West Lines.

AI generated

SINGAPORE – In the wee hours every day, a yellow robot-like machine the size of a train cabin whirs steadily as it clamps rails together and fuses them in an open yard at Ulu Pandan Depot near Bukit Batok.

The flash butt welding machine can clamp down on and weld – or join – rail ends together to complete a rail replacement operation within 15 minutes – more than two times faster than manual welding,

Rails need to be changed whenever there are flaws on the tracks caused by the movements of the trains or braking, as well as natural wear and tear over time.

The machine – acquired by rail operator SMRT for more than $1 million in February – is now being used to weld together five to six pairs of 18m rails each night at Ulu Pandan Depot, before they are transported to sites that require rail changes.

These rails are used to replace parts of the tracks on the North-South and East-West lines (NSEWL), Singapore’s oldest lines, which have been in operation for 37 years and have the highest demand for rail changes among those operated by SMRT.

The Thomson-East Coast and Circle lines, which SMRT also runs, do not require such extensive rail changes as they are newer, added the operator.

The new machine is named after the function it performs: passing electric power (“flash”) through the rail ends (“butts”).

Rail maintenance has been in the spotlight following a spate of at least 15 disruptions from July to September.

Before that, a major disruption occurred in September 2024 when the wheels of a train’s undercarriage ran off the rails on the East-West Line and severely damaged 2.55km of tracks and trackside equipment, halting train service along a stretch of the line for six days.

SMRT said one flash butt welding machine is currently sufficient for the MRT lines it operates.

The machine aligns the rails before passing electricity through them to heat and fuse them together. This makes the welds more durable, SMRT said, because no filler or foreign material is required to fill the gap between the welded rails – unlike manual welding, which involves the addition of aluminium and iron oxide.

A welded rail track.

ST PHOTO: ARIFFIN JAMAR

At a media demonstration on the morning of Oct 23, Mr Guan Junwei, deputy director of track infrastructure maintenance at SMRT Trains, told reporters that the new machine will improve SMRT’s efficiency in track maintenance by 20 per cent.

Besides offering time savings, flash butt welding needs only two workers to operate the machine, while manual welding typically requires four.

SMRT has trained six technicians and two engineers to operate this new machine.

SMRT said one flash butt welding machine is currently sufficient for the MRT lines it operates.

ST PHOTO: ARIFFIN JAMAR

SMRT carries out rail change operations along five stretches of track every night, and two to three of these nightly operations utilise rails that were welded by the new machine.

By the first quarter of 2026, SMRT will transport the new machine onto the viaducts of the NSEWL on a wagon to perform on-site welding during engineering hours from 1.30am to 4.30am.

The machine – measuring 2.4m high, 2.6m wide and 7.3m long – will have to be modified to operate safely within these tight spaces.