Half of piling work on foundation of North-South Corridor viaduct completed: LTA

Sign up now: Get ST's newsletters delivered to your inbox

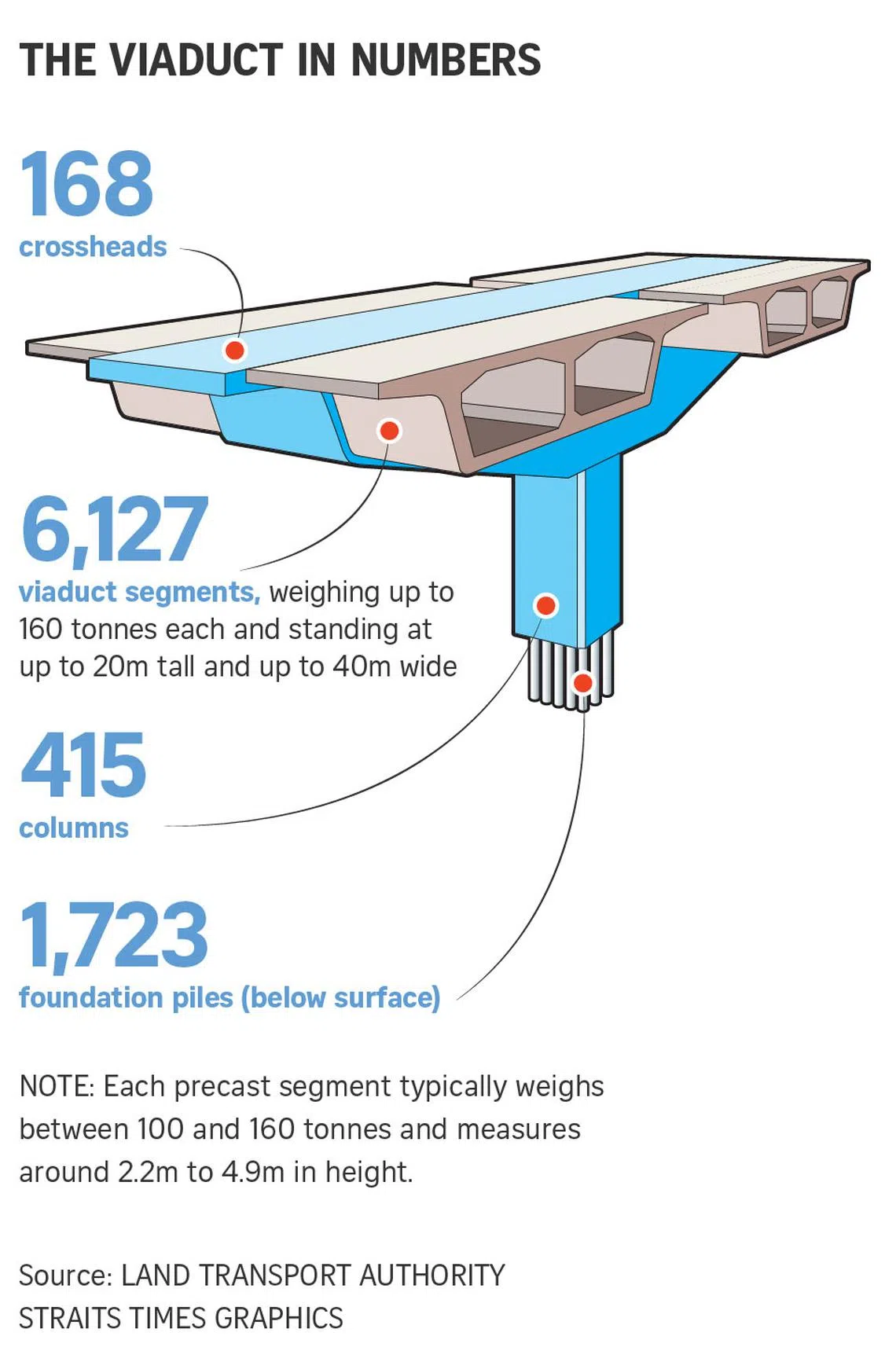

The works include installing columns and crossheads, which are horizontal beams on top of pillars that support the viaduct.

ST PHOTO: AZMI ATHNI

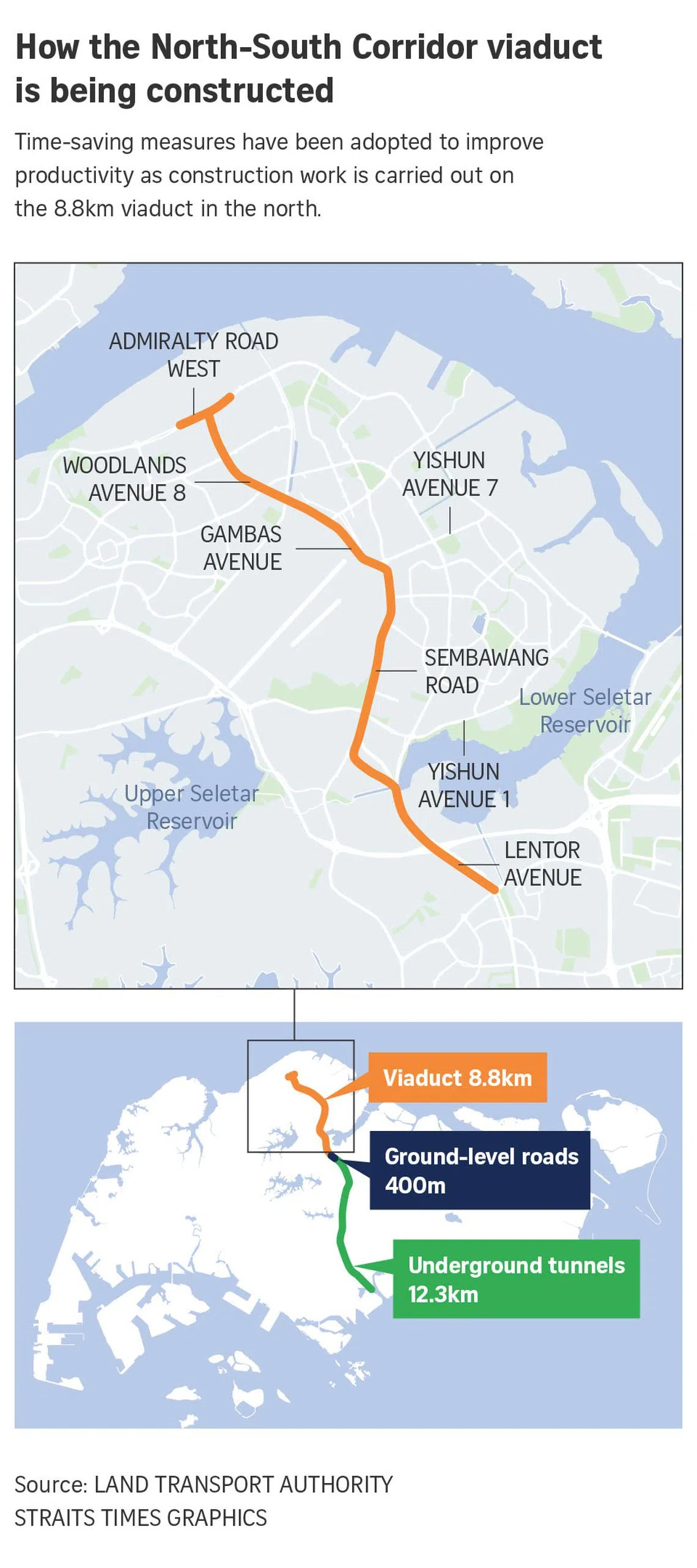

SINGAPORE – Half of the piling work on the foundation of an 8.8km viaduct section of the North-South Corridor (NSC) has been completed, said the Land Transport Authority (LTA).

Mr Chris An, a deputy director for the NSC at LTA, said these works began in the last quarter of 2021 and have since progressed across the entire viaduct.

Above-ground structural works on the viaduct also started along certain stretches of Lentor Avenue and Sembawang Road in the second quarter of 2023, LTA told The Straits Times.

These works include installing columns and crossheads, which are horizontal beams on top of pillars that support the viaduct.

Mooted as an expressway in 2008 and redesigned as a “transit priority corridor” with dedicated bus lanes and cycling trunk routes in 2016, the 21.5km NSC will cut travel time from Woodlands, Sembawang, Yishun and Ang Mo Kio to the city by up to 30 minutes when completed.

Comprising an 8.8km viaduct, 400m of ground-level roads and 12.3km of underground road tunnels, the corridor will be completed in phases from 2027.

The viaduct, running from Admiralty Road West to Lentor Avenue, is expected to be ready in 2027, followed by the road tunnels – from Lentor Avenue to East Coast Parkway – which will be completed in 2029.

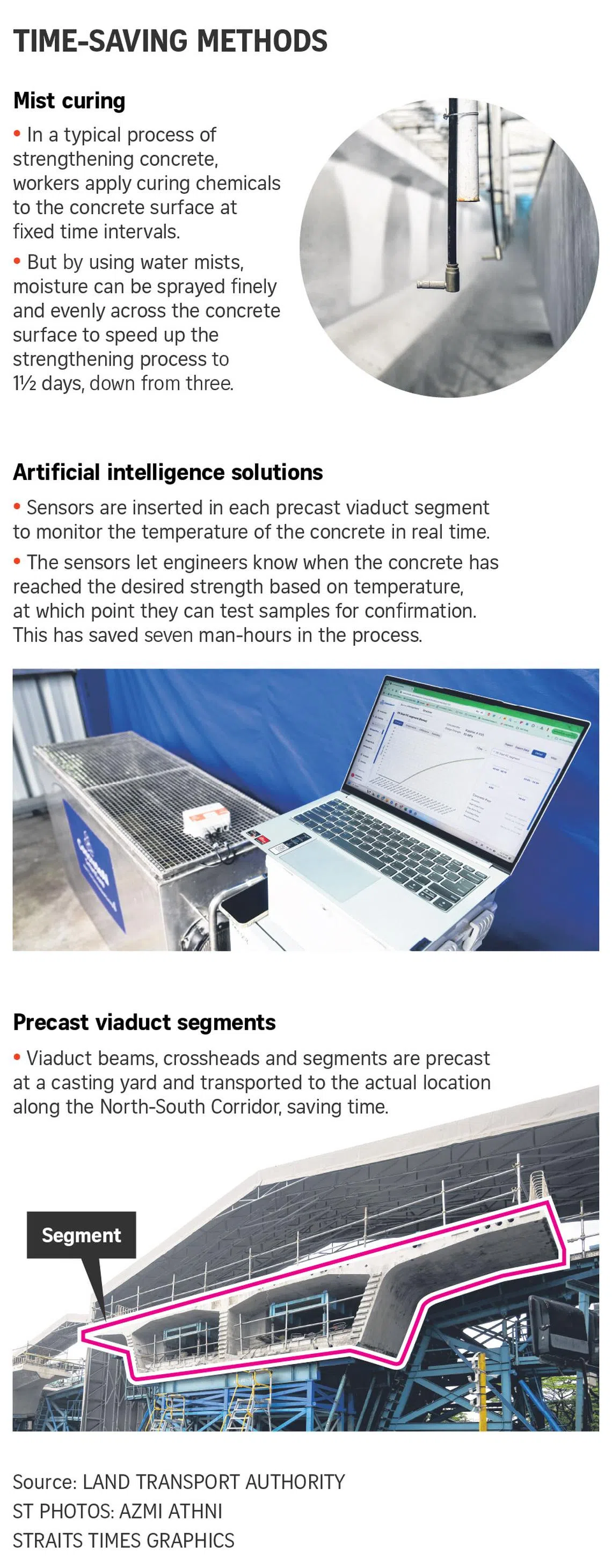

The authorities have incorporated several time-saving steps into the viaduct’s construction.

Among them is a fully automated 360-degree rotating lifting device used to hoist and attach viaduct segments to vertical columns. The use of this device reduces the time taken to hoist and attach each segment from a maximum of three hours to 2½ hours.

Instead of deploying more than five workers to adjust the segment manually with ropes tied to the beams, the lifting device can be operated by just one worker via a remote control.

Another measure is precast production of viaduct segments.

This entails pouring concrete into a mould and pre-assembling reinforcement bar cages to support the structural integrity of the precast segment at a casting yard before transporting the completed segment on trailers to the construction site.

Workers at the precast yard in Admiralty Lane where the components for the NSC viaduct are being made on Nov 26.

ST PHOTO: AZMI ATHNI

To shorten the time taken to produce each precast segment, the concrete-strengthening process – in which a segment gains enough strength to support its own weight and withstand movement – for one viaduct segment happens at the same time as the assembly of reinforcement bar cages for another segment.

LTA said it has prefabricated structural elements as much as possible to save time and space, and minimise the installation of temporary structures on-site for the strengthening of concrete.

Separately, innovations to raise productivity have been adopted in the production of precast viaduct parts, such as mist curing, or spraying water in a fine mist on concrete surfaces to quicken the strengthening of concrete.

Water hoses spray water regularly and evenly across the surface of each concrete slab, halving the time taken for the strengthening process from three days to 1½ days.

Conventionally, workers would need to apply curing chemicals to the surface of a concrete slab at fixed intervals to help it retain moisture and gain strength quickly.

This is used only on precast viaduct beams for the section of the viaduct along Gambas Avenue.

Artificial intelligence (AI) is also used, with temperature sensors inserted in each precast segment to monitor its real-time temperature to determine when the concrete has fully strengthened.

Typically, engineers need to carry out tests on samples extracted from a batch of fresh concrete at fixed intervals, and this involves a lot of trial and error. But with the AI technology, these tests are done only when the concrete reaches certain temperatures, removing the possibility of running premature tests.

This saves about seven man-hours for each viaduct segment.

On the sustainability front, LTA is using low-carbon concrete, with a quarter made up of the waste by-product of steel mill manufacturing, to reduce the amount of carbon dioxide from the construction of the viaduct.

Additionally, the authority has set up a retractable shed to protect workers from bad weather.

When asked if safety measures have been stepped up after several NSC worksite incidents, including one in September where two workers were killed at a Lentor Avenue worksite

On the number of upcoming traffic diversions needed to enable the building of the NSC viaduct, Mr An said that will “depend on the progress of construction”.

He added that LTA will keep affected residents and motorists updated ahead of time through circulars and signs on-site.

These traffic diversions are needed to free up space and facilitate the foundational and structural works of the viaduct, such as lifting operations. During such operations, Mr An said traffic has to be diverted to another road to ensure public safety, as each precast segment can weigh between 100 and 160 tonnes.

He noted that these diversions normally happen from 11pm to 5.30am.

Road closures are imposed only when traffic cannot be diverted to another lane, and these will occur from 1am to 5.30am to minimise inconvenience, added Mr An.