Bukit Panjang LRT renewal 88% done; power rail replacement slated for Q4 2026 completion

Sign up now: Get ST's newsletters delivered to your inbox

This is the first time the power rail system is being replaced since the Bukit Panjang LRT started operations in 1999.

ST PHOTO: AZMI ATHNI

Follow topic:

- BPLRT renewal is 88% complete, with a new signalling system fully operational since November 2025 and a refreshed train fleet.

- Power rail replacement is 20% done and expected to complete by Q4 2026, involving manual work during limited overnight windows.

- Upgrades aim for smoother rides and better reliability for passengers.

AI generated

SINGAPORE – Renewal works for the Bukit Panjang LRT (BPLRT) that started in 2018 are about 88 per cent complete.

The BPLRT has operated fully on a new communications-based train control signalling system since Nov 8, the Land Transport Authority (LTA) said on Nov 15.

A fleet refresh was also completed in October, with all 19 first-generation light rail vehicles replaced by third-generation ones, and all 13 second-generation light rail vehicles upgraded to be compatible with the new signalling system.

What remains is the replacement of the power rail, which supplies electricity to the trains. Around a fifth of the work has been carried out, with completion slated for the fourth quarter of 2026.

This is the first time the power rail system is being replaced since BPLRT started operations in 1999, said LTA.

BPLRT will also migrate to an upgraded operations command centre after renovation works are complete.

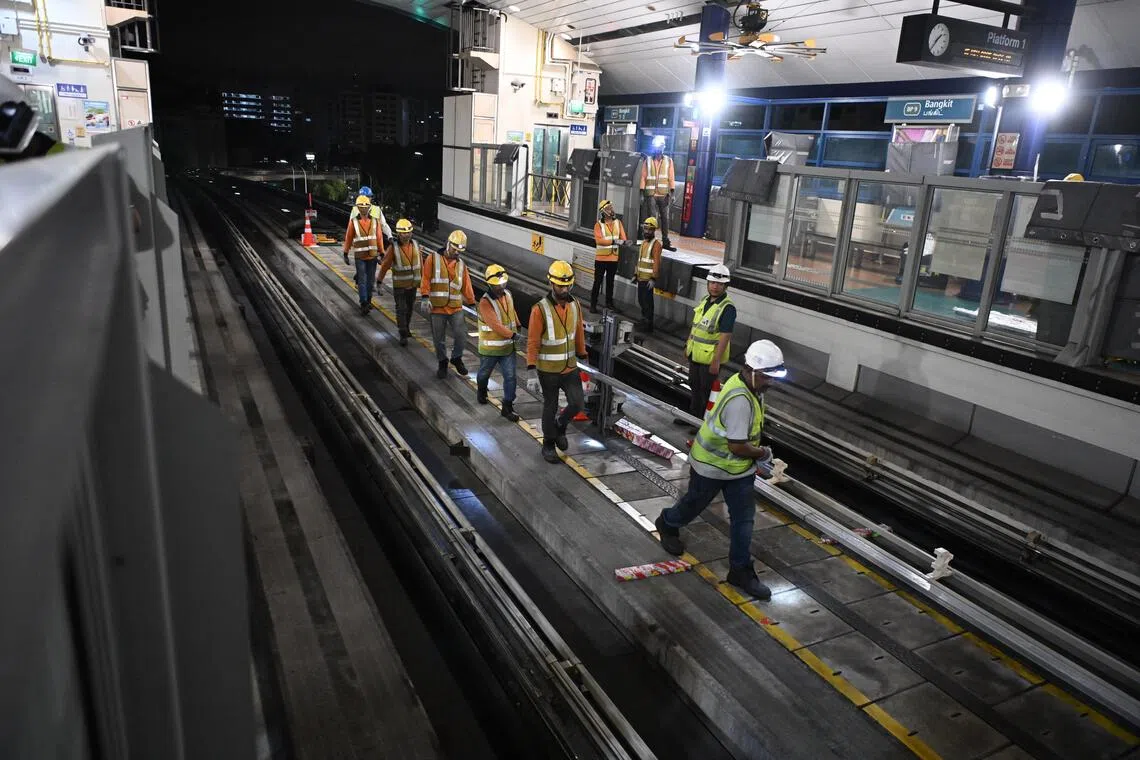

Reporters were shown how power rails were replaced during a visit to the BPLRT tracks between Bangkit and Fajar stations in the early hours of Nov 15.

Workers carrying a 9m-long power rail rod into Bangkit LRT station on Nov 15.

ST PHOTO: AZMI ATHNI

At around 12.15am at Bangkit LRT station, nearly 50 workers began unloading power rail rods and equipment delivered by lorry from a warehouse in Tuas.

This process took around an hour due to the sheer amount of equipment involved, and the 9m rail rods were challenging for workers to manoeuvre through the station’s tight spaces up to the platform.

The station’s handrails, lifts and ticketing service kiosks were covered with protective sheets to prevent them from being damaged.

The race against time started the moment access to the tracks was granted, after the last train reached the Ten Mile Junction depot. Every night, workers have a short window of around 2½ hours until 3.15am to complete their work.

At the tracks near the platform, a group of workers assembled the 9m power rails, which involves slotting five power rods together into frames, while about 150m away, another group worked inside narrow noise enclosures to cut out segments of the track’s existing power rail.

Workers called out “push, push, push”, and used hammers to pound the ends of the rods as they assembled the rails by hand.

Workers assembling five rail rods to form a power rail segment on the tracks at Bangkit LRT station on Nov 15.

ST PHOTO: AZMI ATHNI

Guided by one marshal each at the front and back, six workers lifted and carried the assembled rail segments, which weighed around 120kg each, walking along the tracks to the spot where the rail was being replaced.

The workers lay down their load for a mandated midpoint break, which was, for a minute or so at a curved segment of the track.

The new rail segments were then welded securely to the tracks.

The edges of the removed rail sections were filed blunt, before workers transported them back to the platform to be scrapped elsewhere.

Each night, about 45m of the power rail – about 0.26 per cent of the BPLRT network’s 17km power rail – is replaced.

Workers cutting segments of the existing power rail inside a noise enclosure.

ST PHOTO: AZMI ATHNI

On BPLRT’s renewal, Mr Ganeshan Theveindran, principal project manager at LTA, said: “These upgrades will enhance the reliability of the system and improve the daily commuting experience for the residents.”

The 26-year-old network – operated by SMRT – has had a long history of reliability issues, with two recent trip-ups in July across all 13 stations

Both incidents were linked to the newly installed system that monitors and controls power distribution across the BPLRT.

Things have improved, however, with LTA’s latest rail reliability figures

Improved NEL rail replacements

The North East Line also saw some rail segments being replaced on Nov 16.

The media was invited to Buangkok MRT station that night to witness the deployment of a new embedded rail system.

Previously, the rail replacement process at 13 of the line’s MRT stations, including Buangkok, was complicated as these stations also double as civil defence shelters during national emergencies.

These stations are equipped with blast doors, which means the rails underneath the doors have to be embedded into the concrete base to ensure an airtight seal when the doors are shut during emergencies.

To replace these rails, crews would have to cut through an elastomer compound securing the rail, remove the track segment, pour fresh material, and wait for it to cure. The entire process required four engineering nights.

The new system uses elastic, resin-bonded rubber profiles that can be partially prefabricated off-site. On-site, fast-curing concrete that cures in one hour is poured to secure the track. This simplifies the replacement process and requires only two engineering nights to complete.

Beyond installation efficiency, the new system is also better able to absorb shock and distribute train loads more evenly, reducing vibration and wear. This translates to fewer train defects, longer service life and smoother rides for commuters.