SUTD professor designs 3D-printed ‘trees’ for S’pore pavilion at COP28

Sign up now: Get ST's newsletters delivered to your inbox

3D printing was optimal as it allows full control over the design process and significantly reduces material wastage.

PHOTO: PICO GROUP

SINGAPORE – Two “trees” made of stainless steel and upcycled plastic waste stood at the Singapore pavilion during the recent United Nations COP28 climate conference

Designed by Associate Professor Carlos Banon from the Singapore University of Technology and Design (SUTD), the 3D-printed trees were the pavilion’s centrepiece from Nov 30 to Dec 12.

Their design is supposed to embody Singapore’s connection to nature and efforts in sustainability, said Prof Banon, who is associate professor of architecture and sustainable design at the university.

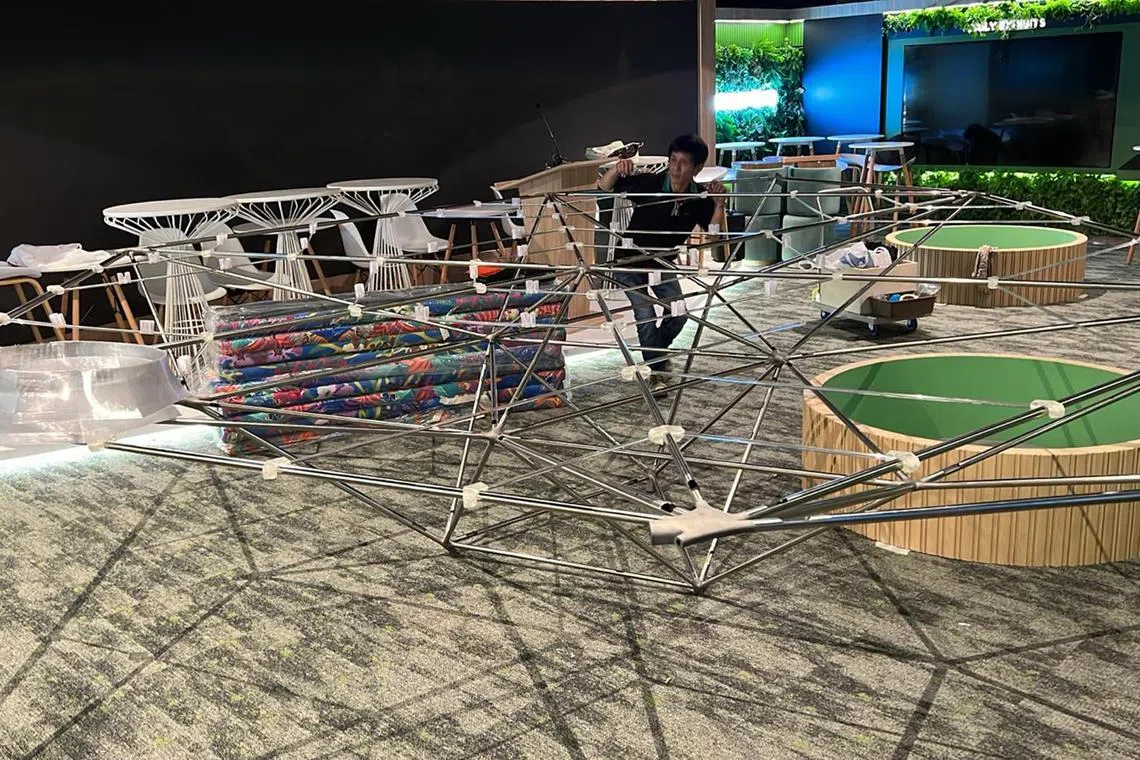

The main part of each tree consisted of bars which were connected by stainless steel nodes that were 3D-printed to form the trunk of the tree design. This was paired with tiles which were also 3D-printed, using recycled plastic waste, to form the canopy and green facades.

Prof Banon told The Straits Times that the nodes joining the bars were the most complex to print, as each node needed to be precise to intersect and hold the many bars together safely.

3D printing was optimal as it allows full control over the design process and significantly reduces material wastage, he said.

“We can actually print only what we want or only where we want, so we avoid areas that don’t need materials. This way, we can save about 80 per cent of the material, compared (with) standardised structures,” he added.

In total, the two trees in the structure consisted of 212 standard stainless steel bars, 58 3D-printed stainless steel nodes and 162 3D-printed tiles made from upcycled plastic waste.

“It showcases upcycling by using waste materials for the cladding components, demonstrating how 3D printing can repurpose waste beautifully,” said Prof Banon.

Initially, he faced challenges because the location for the structure took longer than expected to be confirmed.

“We had to keep the design very fluid because every other month, there was a change in the venue, and then it was a completely different size. So that was a challenge. But it was also a very good way to test the adaptive system that we used, where we can configure changes in very little time,” he said.

The centrepiece was also designed for easy assembly and disassembly, so that it can be conveniently relocated and displayed at different locations.

The individual components were manufactured entirely in Singapore – mostly in SUTD’s printing labs – and shipped in compact parts to Dubai for display.

Prof Banon said: “Each component was marked with a reference code, making assembly as straightforward as connecting pieces of Ikea furniture.”

The structure was assembled in only one day in Dubai by a team of four people, he added.

The main part of the installation consisted of bars which were connected by 3D-printed nodes to form the trunk of the tree design.

PHOTO: PICO SINGAPORE

After the conference, the structure was disassembled and brought back to Singapore; it will be displayed at a bigger venue which has yet to be confirmed.

Prof Banon said he received positive feedback about the structure.

“It is nice that it is sitting there quite silently, and not taking over the space. Yet it generates conversation as it is visually striking and features concepts of sustainability. It definitely sparks conversation.”

Ms Hannah Lim, 20, a second-year undergraduate in engineering systems and design at SUTD, was part of a team that helped with the 3D printing of some of the structure’s components.

She said that since she lived in the university’s dormitory that was close to the 3D printing labs, she could go down at odd hours of the night to check on the progress of the printing and start new prints that would run throughout the day.

“There’s a lot of potential that’s yet to be unlocked with 3D technology,” she said.

Ms Lim added that her experience has inspired her to do more research on how 3D printing uses environmentally friendly materials like PLA – a polyester made from renewable biomass – instead of traditional plastics to reduce carbon footprint.