ST Explains: Different types of fermentation tech and their nutritional benefits

Sign up now: Get ST's newsletters delivered to your inbox

Perfect Day’s Very Dairy is the first precision fermentation milk available in Asian supermarkets. The milk is made from microflora.

PHOTO: PERFECT DAY

SINGAPORE – Fermentation-based proteins are proving to be an up-and-coming alternative protein source, with growing investor interest in the first half of 2024.

Figures show investments in the fermentation sector surged during that period, driven mostly by investments in biomass and precision fermentation start-ups, outpacing those of cultivated meat and plant-based proteins for the first time.

According to alternative protein think-tank The Good Food Institute (GFI), US$398 million (S$511 million) was invested in fermentation companies globally in just the first half of 2024, compared with US$130 million for cultivated meat and US$138 million for plant-based proteins. In comparison, US$443 million was invested in fermentation companies in the whole of 2023.

The Bezos Centre for Sustainable Protein was launched on Sept 5 at the National University of Singapore, backed by $39 million from the Bezos Earth Fund. The National Research Foundation (NRF) pumped in some US$14.8 million in June 2024 for a new Centre for Precision Fermentation and Sustainability (PreFerS).

Q: What is the difference between biomass and precision fermentation, and what payoffs do they offer?

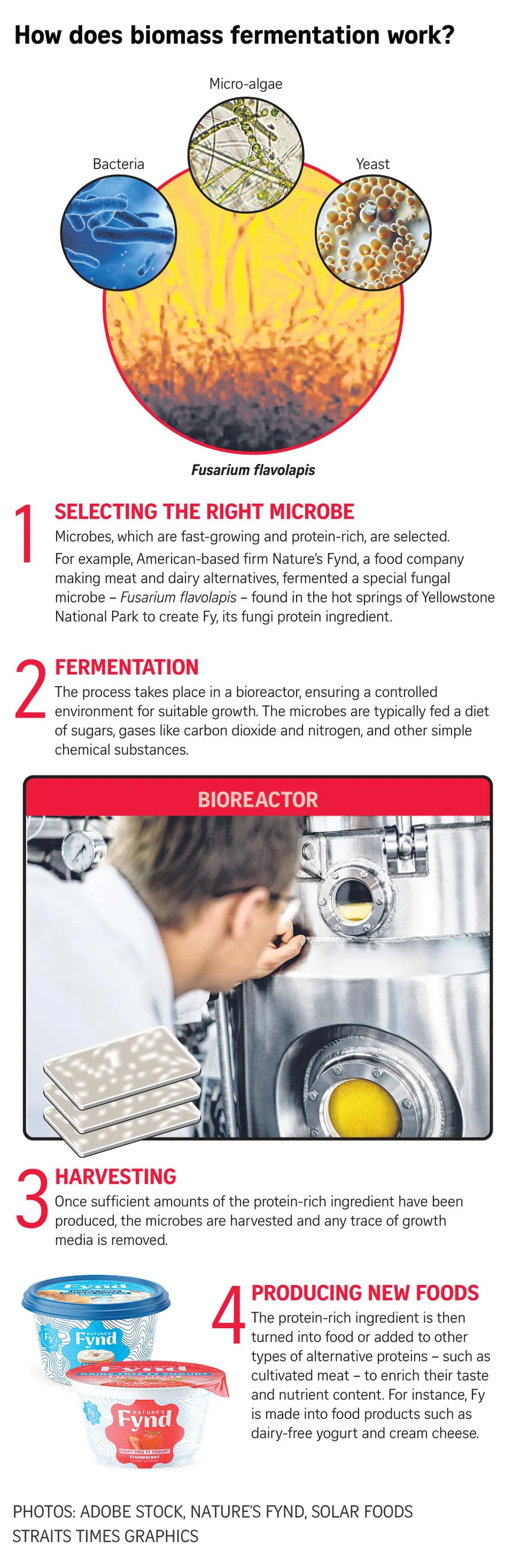

A: Similar to the ways in which cultured products like yogurt and cheese are made, biomass fermentation involves creating new food products by growing protein-rich microbes in a bioreactor for direct consumption.

There has been an increased focus in using mycelium or fungi as the microbe for fermentation, given its naturally high protein content and ability to multiply rapidly.

Dr Simon Eassom, chief executive at alternative protein think-tank Food Frontier, said biomass fermentation plays a big and important role in the plant-based meat sector, as companies like Quorn have demonstrated.

Products from such fermentation processes, like Quorn, are relatively cheap to produce and compare well for taste and texture, he added. In Britain, Quorn came up top for being the cheapest meat alternative, compared with other brands, according to a 2021 survey.

The fungus-derived protein, which is the primary ingredient in Quorn products, has a very desirable nutritional profile – containing essential amino acids and fibre, while being low in fat, said Ms Mirte Gosker, Asia-Pacific managing director at GFI.

“Those attributes, if effectively combined with the meaty textural qualities of certain plant proteins, have the potential to create an end product greater than the sum of its parts,” she added.

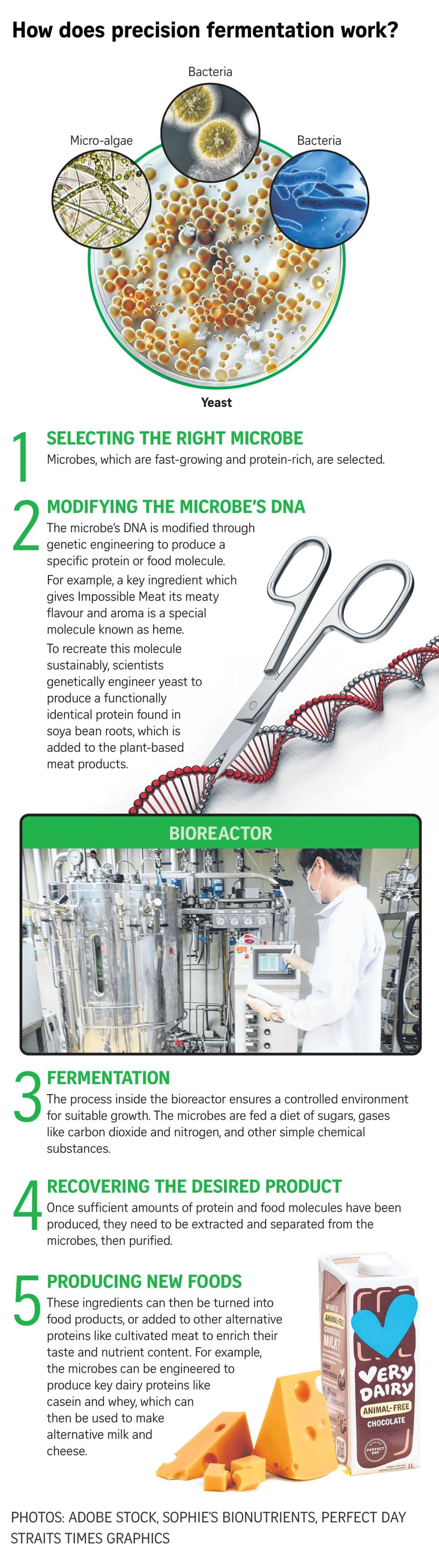

Precision fermentation entails leveraging microbes as cell factories to produce a range of food ingredients, like protein.

The PreFerS centre was set up to tackle the key challenges in the precision fermentation production process.

Professor Subodh Mhaisalkar, NRF’s executive director of academic research, said the programme hopes to address the issue of “hidden hunger” or micro-nutrient deficiencies which can arise from an energy-dense but nutrient-poor diet, with precision fermentation capable of producing both macro- and micro-nutrients needed to meet these nutritional goals.

Macro-nutrients are the nutrients that your body needs in large amounts, which include fat, carbohydrates and protein, while micro-nutrients are vitamins and minerals needed in smaller amounts.

“The programme goals are also aligned with Singapore’s ‘30 by 30’ vision of producing 30 per cent of our nutritional needs locally by 2030,” added Prof Mhaisalkar.

Ms Gosker said precision fermentation techniques can also be used to supercharge existing products in ways that consumers notice and appreciate.

For instance, this approach has been demonstrated with the use of fermentation-derived heme that Impossible Meat uses in its plant-based meat products and which gives the meaty taste and aroma, she noted. “Precision fermentation has the ability to bring all alternative proteins closer to taste parity, which is a non-negotiable factor for Singapore’s discerning diners,” she added.

Q: What are some present barriers to scaling up these fermentation-based technologies?

A: Biomass fermentation is currently more cost-effective than precision fermentation because of the shorter downstream process needed to harvest the microbes post-fermentation, compared with the expensive techniques needed to purify precision-fermented proteins.

Yet, biomass fermentation-produced ingredients are not incorporated with plant-based meat and cultivated meat at a significant volume, as there is a big knowledge gap in doing so effectively, said Ms Gosker.

This is an area which the Bezos Centre for Sustainable Protein will seek to address, by smoothening out hurdles faced with incorporating plant-based protein and cultivated meat with biomass fermentation ingredients, she added.

This could help meet consumer expectations on taste and nutrition and potentially solve challenges pertaining to the price and accessibility of these alternative proteins, said Ms Gosker.

Most of the knowledge gaps for precision fermentation are at the foundational research and development stage, she noted.

For example, to use microbes as mini-factories, producers need to identify the target output that the factory will produce, whether it is enzymes or proteins, and determine the “type of factory” needed to produce them.

To be successful, producers need to identify the optimal “type of factory” that can both thrive in a bioreactor, and produce the target output at a reasonable yield to be commercially viable, she added.

Dr Maybelle Kho Go, principal research scientist and programme manager for PreFerS, said there are still challenges in the economic feasibility and environmental sustainability of the precision fermentation processes.

“The centre will address these challenges by optimising fermentation conditions, and its corresponding downstream processes. We will also ensure that the processes are environmentally sustainable,” she added.