NTU professor first Singapore winner of Apec science prize

Sign up now: Get ST's newsletters delivered to your inbox

Professor Liu Zheng receiving the 2023 Aspire prize in the US earlier this month.

PHOTO: ASIA-PACIFIC ECONOMIC COOPERATION

SINGAPORE – A Singaporean scientist who developed a cost-effective and sustainable material that can be used for green hydrogen energy,

Professor Liu Zheng, 40, from Nanyang Technological University’s (NTU) School of Materials Science and Engineering, beat 15 other nominees to win the 2023 Asia-Pacific Economic Cooperation (Apec) Science Prize for Innovation, Research and Education (Aspire).

Apec Aspire awards young scientists for their scientific research and scholarly publications, as well as collaboration with other scientists from the 21 Apec member economies, which include Vietnam, Japan and Australia.

The prize is worth US$25,000 (S$34,000).

The award ceremony took place earlier in Seattle in the United States.

Prof Liu was recognised for the relevance of his research to this year’s theme of Inclusive Science, Technology, and Innovation for a Resilient and Sustainable Environment.

He told The Straits Times he feels lucky that his work aligned well to the theme chosen by the US as the host of this year’s award, and is encouraged by the global recognition it brings.

His research centres on the application of sustainable 2D materials that are just one atom thick. Prof Liu found that the two-dimensional structure of this material is useful in improving green energy generation, and the semiconductor industry.

For instance, 2D platinum can be used as a highly efficient catalyst to produce hydrogen used as a form of green energy.

Traditionally, platinum is used as a catalyst in the reaction, making it a costly process, as 1g of platinum costs around US$31. Assuming 1g of platinum is needed to make a catalyst conventionally, using selenium to create a 2D platinum catalyst requires only 0.25g of platinum. This lowers the platinum costs as a smaller amount of platinum is used, but maintains the efficiency of the hydrogen generation process.

With Singapore setting its sights on achieving net-zero carbon emissions

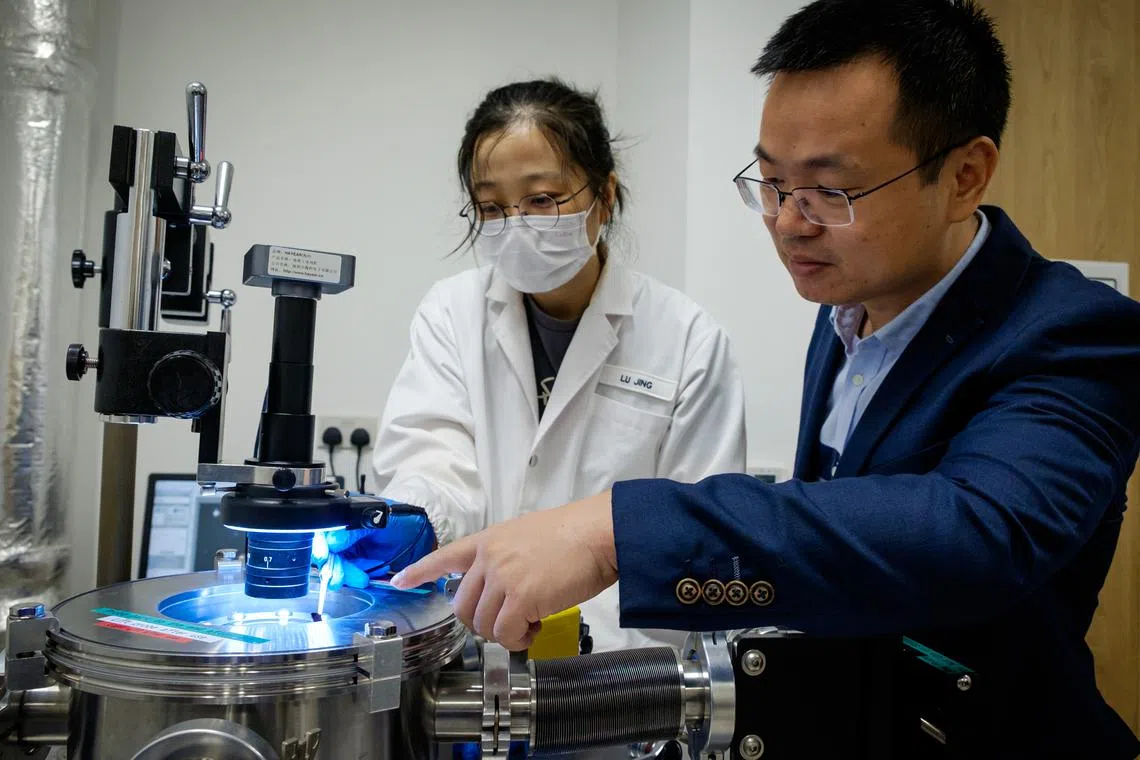

Prof Liu Zheng (right) found a way to produce hydrogen that uses less platinum, a costly material that is used as a catalyst in hydrogen production.

PHOTO: NTU

Prof Liu’s technology can also be used in the semiconductor industry to make a transistor with 2D materials such as molybdenum disulfide, graphene, and boron nitride.

Transistors made of semiconductor materials are used to regulate the flow of electricity in most electronic devices, such as smartphones, hearing aids and cameras.

Using 2D semiconductor materials is a more sustainable alternative that facilitates more efficient energy use as they have less resistance than the thicker silicon that is typically used, said Prof Liu.

Singapore plays a major role in semiconductor production,

By reducing energy consumption in electronics like smartphones or smartwatches, these devices will have increased battery life by up to 90 per cent.

Having begun his research when he joined NTU in 2013, Prof Liu manages a group of more than 10 research fellows and PhD students who help him in both arms of his 2D material research.

Prof Liu said his next step is “to implement this technology on a larger scale”.

“Eventually, we want to (use the 2D material to) make a real product that can benefit everyone,” he said.