Dutch firm opens vertical farm in Changi, hopes to have greens in stores by December

Sign up now: Get ST's newsletters delivered to your inbox

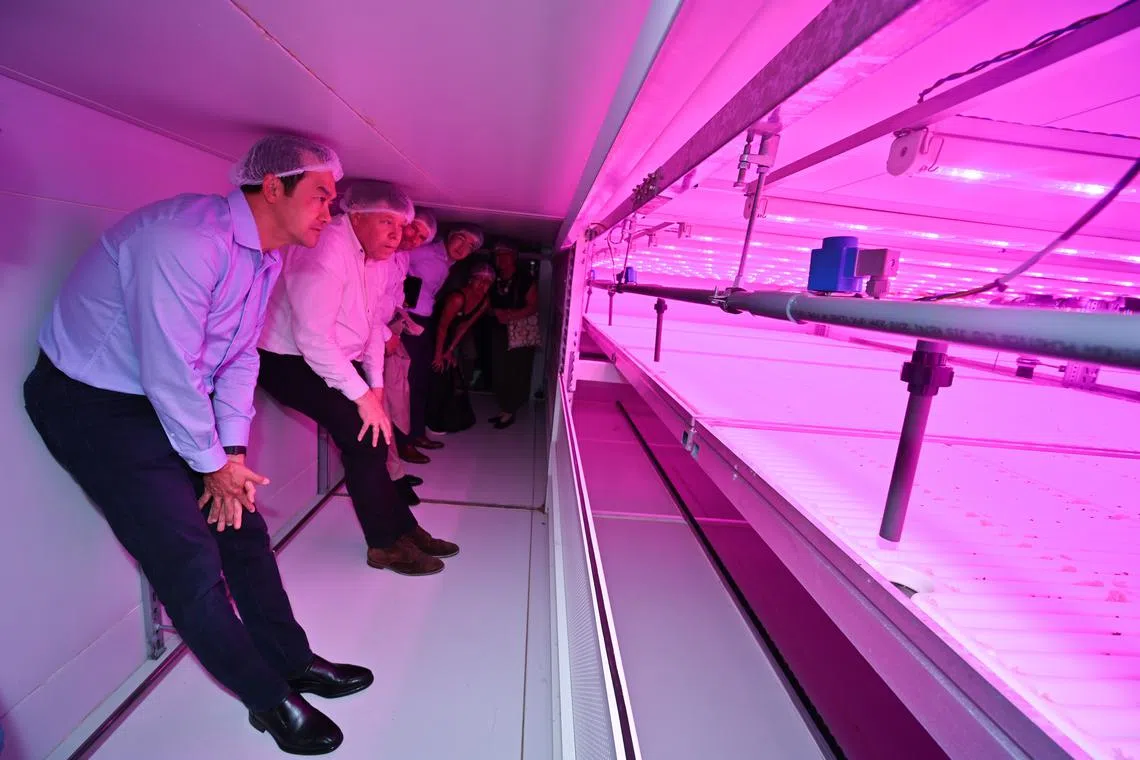

Senior Minister of State for Sustainability and the Environment Koh Poh Koon (left), accompanied by Growy founder and CEO Ard van de Kreeke, touring the firm's indoor vertical farm.

ST PHOTO: LIM YAOHUI

Follow topic:

SINGAPORE – A new farm has sprouted in Changi, producing greens such as basil, parsley, shiso and amaranth, along with baby leaf varieties such as kale.

While times have been rocky for farms in Singapore, Dutch agritech company Growy hopes to reach full production capacity of 500 tonnes of leafy greens per year by April or May 2025.

It bought over the partially completed indoor vertical farm in Changi Logistics Centre

Operating under the Chef’s Farm brand from Amsterdam, Growy currently supplies more than 30 different products, including herbs, microgreens, baby leaves and salad mixes to about 50 local hotels and restaurants.

The company plans to enter the retail market by December and sell its produce in supermarkets such as FairPrice, Cold Storage and Little Farms, said Mr Ard van de Kreeke, Growy’s founder and chief executive.

Microgreen mixes served during the opening of Growy’s indoor vertical farm on Nov 15.

ST PHOTO: LIM YAOHUI

Singapore has a “30 by 30” sustainable food security goal,

But though vertical farming is a promising concept in land-scarce Singapore, not all farms have found it smooth-going.

One of them, VertiVegies, abandoned its plans to build an indoor vertical farm in Lim Chu Kang

In April, indoor farm I.F.F.I closed the doors

While still in business, GroGrace, an indoor vertical farm in Jurong

A bright spot, however, is vegetable farm Artisan Green, which is building a bigger farm in Sungei Tengah come 2025

Local vegetable production accounted for 3.2 per cent of total food consumption in 2023, a decrease from 3.9 per cent in 2022, according to SFA’s annual food statistics report released in May.

With the closing of farms and companies that produce alternative foods in Singapore, Mr van de Kreeke said that local food production is still key for Singapore and his company learnt from their failures.

“Most vertical farms are having difficulties in making money because it’s too expensive and (these) expenses are (spent on) labour, energy and investment. And what we have done here with more efficient investment, lower energy consumption and (less) labour, we made it more viable,” he said.

Speaking at the farm’s opening on Nov 15, Senior Minister of State for Sustainability and the Environment Koh Poh Koon said: “The facility employs a fully automated system to transport seedlings from the preparation room to 16 levels of growing space, and finally to the harvesting area.

“This innovation allows for a lean crew to operate the farm.”

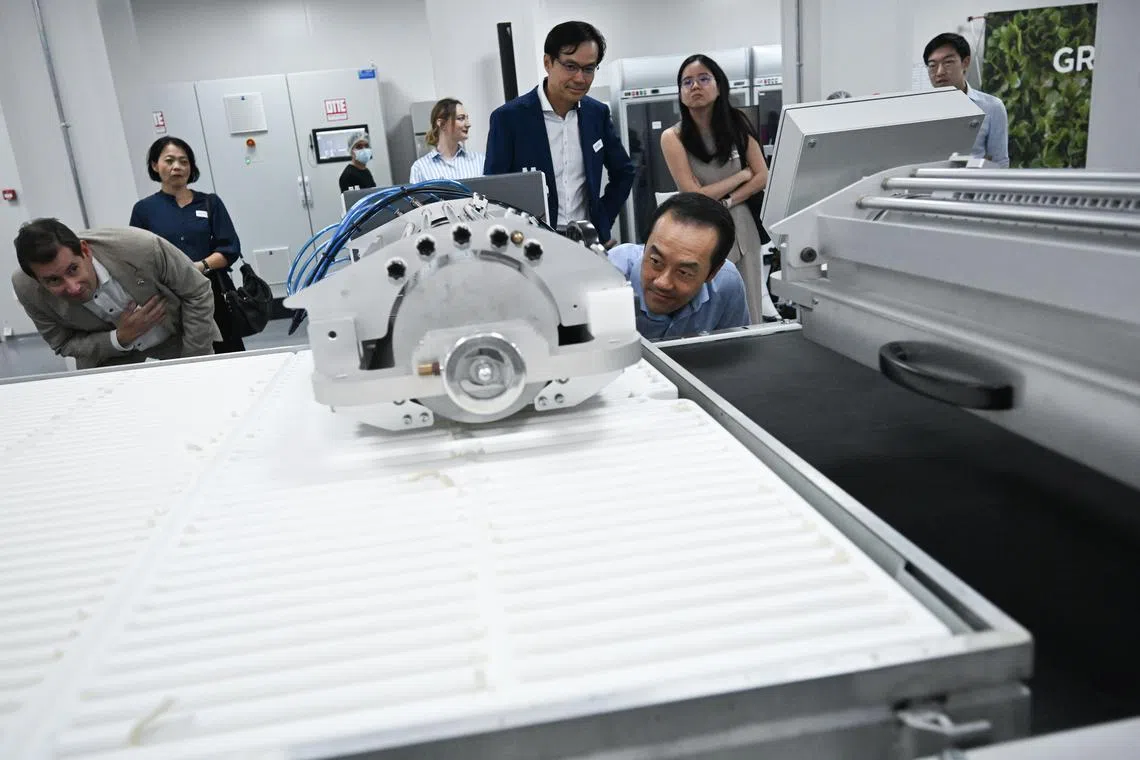

Senior Minister of State for Sustainability and the Environment Koh Poh Koon looking at a seeding drum depositing seeds into the planting bench on a conveyor.

ST PHOTO: LIM YAOHUI

Seedlings grow in 16 levels of growing space in Growy’s four farmhouses.

ST PHOTO: LIM YAOHUI

The growing space in the facility occupies 8,000 sq m and there are about 10 production workers and another 10 employees who are engineers, bioscientists, and administrative and management staff. The company will increase its production staff to about 15 when the facility reaches full production capacity.

Unlike most vertical farms, which set the same conditions such as humidity and temperature for the entire growing environment, Growy has developed different “climate zones” for its greens.

Mr van de Kreeke said: “Every climate zone, every cell has its own climate. By climate, we mean light, carbon dioxide, moisture, temperature, so that we can change and adjust to water (the) plants...

“Most vertical farms provide the plants with the same conditions right from day one till day 21. (But) if you adjust that according to the plants’ needs, you use a lot lower energy.”

Seedlings of greens such as tatsoi, mustards, bok choy and nai bai growing on planting benches in the nursery climate cell of the farmhouse.

ST PHOTO: LIM YAOHUI

Dr Koh said that in addition to regulating temperatures in the farm, the air-handling unit also captures water vapour released by the plants during transpiration, condensing it into water.

“This reclaimed water is used as part of the chiller water, contributing to water conservation and reducing the energy needed to cool the facility,” he added.

Mr van de Kreeke said that the amount of water used to grow 1kg of vegetables in Growy is only 5 per cent of the amount of water used to grow 1kg of vegetables on land in other farms.

Daikon red, a microgreen, on yuzu-infused grilled unagi on toasted butter brioche, served during the farm’s opening.

ST PHOTO: LIM YAOHUI

Growy has plans to build a second vertical farm in Singapore with better technology and lower energy consumption to grow produce such as strawberries, mushrooms and tomatoes.

Mr van de Kreeke said that the company plans to build another three to five farms around the world, including in regions such as Europe, North America and Asia.

Correction note: In an earlier version of the story, we said that the facility occupies 8,000 sq m. It should be the growing space that occupies 8,000 sq m. This has been corrected.