SG•Global

Chip war: The fight over the world’s most critical technology

The US and China may be locking horns today, but competition for semiconductor dominance has gone on for as long as chips have been made.

Sign up now: Get ST's newsletters delivered to your inbox

TSMC announced in 2021 it would build a US$7 billion chip plant in Japan with Sony Group.

PHOTO: AFP

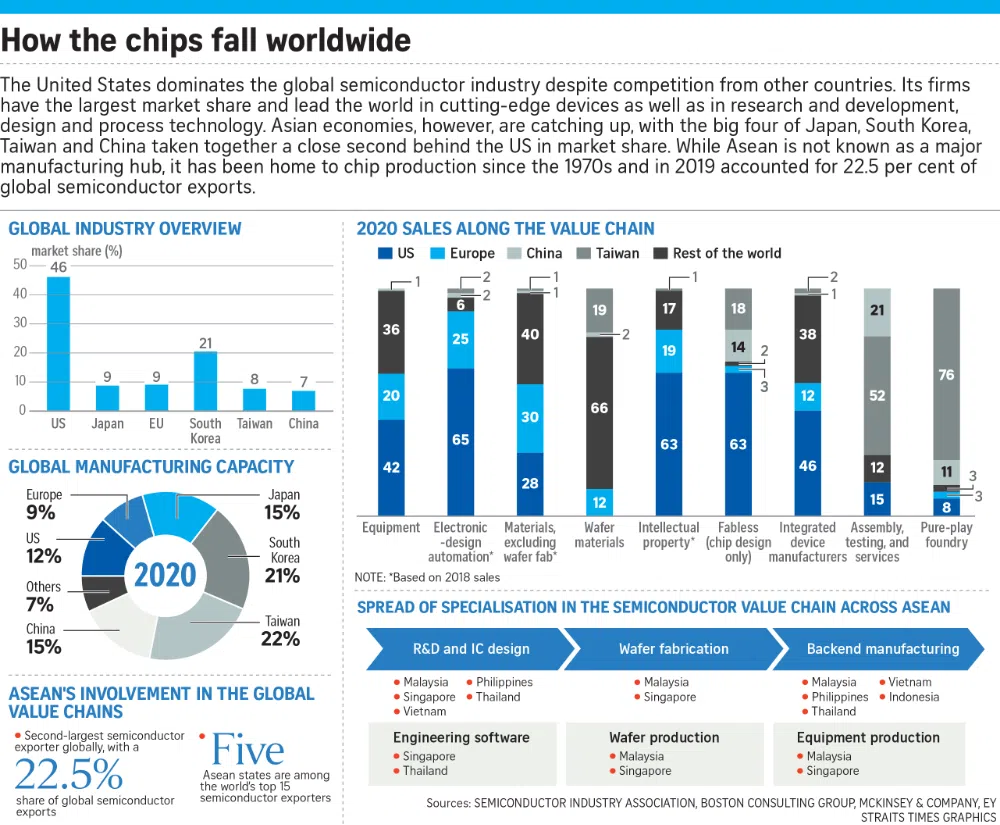

The global network of companies that annually produces a trillion semiconductor chips at nanometer scale is a triumph of efficiency. It is also staggeringly vulnerable.

Taiwan, the world’s biggest producer of advanced chips which are used in everything from cars and smartphones to data centres and fighter jets, sits atop a fault line that as recently as 1999 produced an earthquake measuring 7.3 on the Richter scale.

A devastating quake could also hit Japan, which produces 17 per cent of the world’s chips.

Yet, the most seismic shift that imperils semiconductor supply today isn’t the crash of tectonic plates, but the clash of great powers, as the United States and China struggle for technology supremacy.

On Oct 7, the US announced sweeping export controls

In Chip War, his hugely enjoyable new book, Tufts University historian Chris Miller describes how chips have historically played into American fears of vulnerability, and the political, economic and technological forces that shaped this critical industry.

The competition began in the 1950s and 1960s when the Soviet Union realised that integrated circuits would revolutionise the nature of military power, from surveillance systems to guided missiles. But its strategy to copy US companies, such as Texas Instruments and Fairchild Semiconductor, was fundamentally flawed.

(From left) Gordon Moore, C. Sheldon Roberts, Eugene Kleiner, Robert Noyce, Victor Grinich, Julius Blank, Jean Hoerni and Jay Last. The eight men started Fairchild Semiconductor, a pioneering US manufacturer of transistors and integrated circuits.

PHOTO: WAYNE MILLER/MAGNUM PHOTO

These companies were constantly churning out new designs of greater complexity. As they crammed more and more transistors onto silicon chips, it became harder for the Soviet Union to reproduce them at scale. The Soviets also lacked an international supply chain, unlike the US, which could spread research and development (R&D) and production costs over a larger number of allied countries.

By the 1990s, in the clearest sign that the Russian chip industry had failed to take off, one of its fabrication plants, or “fabs”, was reduced to producing tiny chips for McDonald’s Happy Meal toys. The Cold War was over and Silicon Valley had won.

Competition with Japan

While the US today sees China as a threat, in the 1980s, it was Japan which was the perceived villain.

US and Japan semiconductor industries had grown to rely on each other for supplies and customers. US companies produced the best computers, while Japanese electronics manufacturers such as Sony and Sharp produced consumer goods that drove semiconductor consumption.

TSMC announced in 2021 that it would build a US$7 billion chip plant in Japan with Sony Group.

PHOTO: REUTERS

US officials and business leaders feared that letting Japan acquire advanced technology would undermine US national security. But their fears were trumped by America’s Cold War strategy, which was to build up Japan’s economy so that it wouldn’t have to turn to Communist China or the Soviet Union for help.

Unlike in the US where antitrust law discouraged chip companies from collaborating, the Japanese government launched a research consortium called the VLSI programme in 1976, with the government funding half of its budget. By 1986, Japan had overtaken the US in the number of chips produced.

Meanwhile, US chip companies struggled with inefficient production, and were just not as good as the Japanese at meeting the needs of their customers.

Friendly cooperation turned into rivalry. To the US’ claim of unfair competition – that Japanese companies were selling below production cost and had access to cheap capital – Japan retorted that interest rates were low across its entire economy, not just its chip sector.

One thing was clear: If the US’ high-tech position was deteriorating, its foreign policy position was at risk, too. From its first Fairchild Semiconductor assembly plant in Hong Kong’s Kowloon Bay, to chipmaking facilities from Taiwan to South Korea to Singapore, the US saw these economies as having been shielded from communist influence, not by military force but by economic integration.

It would take ruthless cost-cutting and discipline on the part of US companies such as Micron and Intel to turn things around. As personal computers became ubiquitous in offices and homes, Intel abandoned the memory chips it originally built and established a stranglehold on the market for PC chips.

In a classic case of “my enemy’s enemy is my friend”, most of Silicon Valley was happy to work with South Korean and Taiwanese companies, thereby undercutting Japanese competitors and turning South Korea into one of the world’s leading memory chipmakers.

Japan, however, ignored the microprocessor market until it was too late. By the time its stock market crashed in 1990, its semiconductor dominance was eroding.

ST ILLUSTRATION: MANNY FRANCISCO

The rise of Taiwan’s semiconductor industry

A key figure in the book is Mr Morris Chang, who moved to Taiwan after he was passed over for the chief executive job at Texas Instruments.

Since the 1960s, Taiwan had deliberately plugged itself into semiconductor supply chains, both as a strategy to provide jobs and to strengthen its security relationship with the US. Its government knew that Taiwan’s economy would keep growing only if it advanced beyond simply assembling components designed and fabricated elsewhere, so it hired Mr Chang to establish a cutting-edge chip industry.

Taiwan Semiconductor Manufacturing Co founder Morris Chang stands next to the company’s logo in an undated photograph.

PHOTO: REUTERS

A large portion of the start-up capital for the new chipmaker, Taiwan Semiconductor Manufacturing Co (TSMC), was stumped up by wealthy Taiwanese who were “persuaded” by the government to support the cause.

When one businessman refused to invest after three meetings with Mr Chang, a top official reminded him: “The government has been very good to you for the last 20 years. You better do something for the government now.” A cheque quickly appeared.

Building an advanced logic fab costs around US$20 billion (S$28 billion), an enormous capital investment that few companies can afford. Because Mr Chang promised not to design chips, and to only build them, this allowed an ecosystem of fabless chip design companies – which did not have to bear the astronomical cost of building and maintaining facilities – to flourish around TSMC.

This foundry model, where chip design and manufacturing are separated, set TSMC on the path towards dominating the production of the world’s most advanced semiconductors.

The company now finds itself at the centre of the tech war between the US and China. There are concerns that any conflict between China and Taiwan could lead to a key source of global chip supplies being cut off.

Made in China

The second half of the book delves into the ups and downs of China’s semiconductor ambitions. Although Chinese engineers forged their first integrated circuit in 1965, their dreams died with the Cultural Revolution as they were shipped off to the countryside to be farmers.

China lost precious time denouncing capitalists while its neighbours were desperately courting them. The result was that when rising entrepreneurs like Huawei’s Mr Ren Zhengfei began building electronics businesses in the late 1980s, they had no choice but to rely on foreign chips.

More recently, China’s efforts to build its chip industry have been stymied, not by internal political upheaval but by the US, with companies such as Huawei becoming high-profile casualties of the chip war.

With the help of generous state-backed credit and tax deductions far above what most Western companies get from their governments, Huawei developed efficient manufacturing processes which drove down costs. It also invested world-leading amounts in R&D and kept up with consumer trends.

The issue with Huawei went far beyond the debate over whether the company helped tap phones or steal data. The bigger issue, writes Associate Professor Miller, was whether China, the US’ strategic rival, should be stopped from playing an ever-larger role in the world’s tech infrastructure.

Among all of China’s tech companies, Huawei was the most successful exporter, giving it detailed knowledge of foreign markets. Not only did it produce hardware for cell towers, it also designed cutting-edge smartphone chips. It had also become TSMC’s second-biggest customer after Apple.

Smartphone with a Huawei logo seen in front of a US flag

PHOTO: REUTERS

The Trump administration saw the competition in zero-sum terms. It dubbed Huawei a national security threat, put it on an export blacklist, and barred the company and its suppliers from using US technology and software.

The latest sanctions by current US President Joe Biden are far broader in scope and have wider industry impact, affecting dozens of Chinese companies as well as other countries’ companies that work with them.

There has been debate over whether it is wise for the US to try to derail China’s growing chip ecosystem, thereby spurring an unavoidable counter-reaction and catalysing greater Chinese government support for domestic chipmakers.

But despite its rhetoric, China is unlikely to pursue an all-domestic supply chain. What is more plausible is for it to reduce its reliance on the US and wean itself off as many chokepoint technologies as possible.

China is also focusing on older process technology to build logic chips: Smartphones and data centres require leading-edge chips, but cars and other consumer devices often use older process technology, which is powerful enough and much cheaper.

Interestingly, despite not having access to the most advanced equipment technologies as a result of sanctions, it was reported in 2022 that China’s Semiconductor Manufacturing International Corporation had used 7-nanometre technology to make a Bitcoin mining chip.

The staggering complexity of computing power shows that the story of semiconductors isn’t merely one of science and engineering. Instead, geopolitics shape how chips are researched, designed, produced, assembled, distributed and used.

Government funding of R&D has been, and will continue to be, crucial in advancing chip technology. While China today may still lag behind technologically, state support for its chip industry could profoundly reshape the semiconductor supply chain. This is regardless of whether the US or China – or another player – comes out on top in the chip war.