Torque Shop: Spring rate and ride height can adapt to driving conditions in cars with air suspension

Sign up now: Get ST's newsletters delivered to your inbox

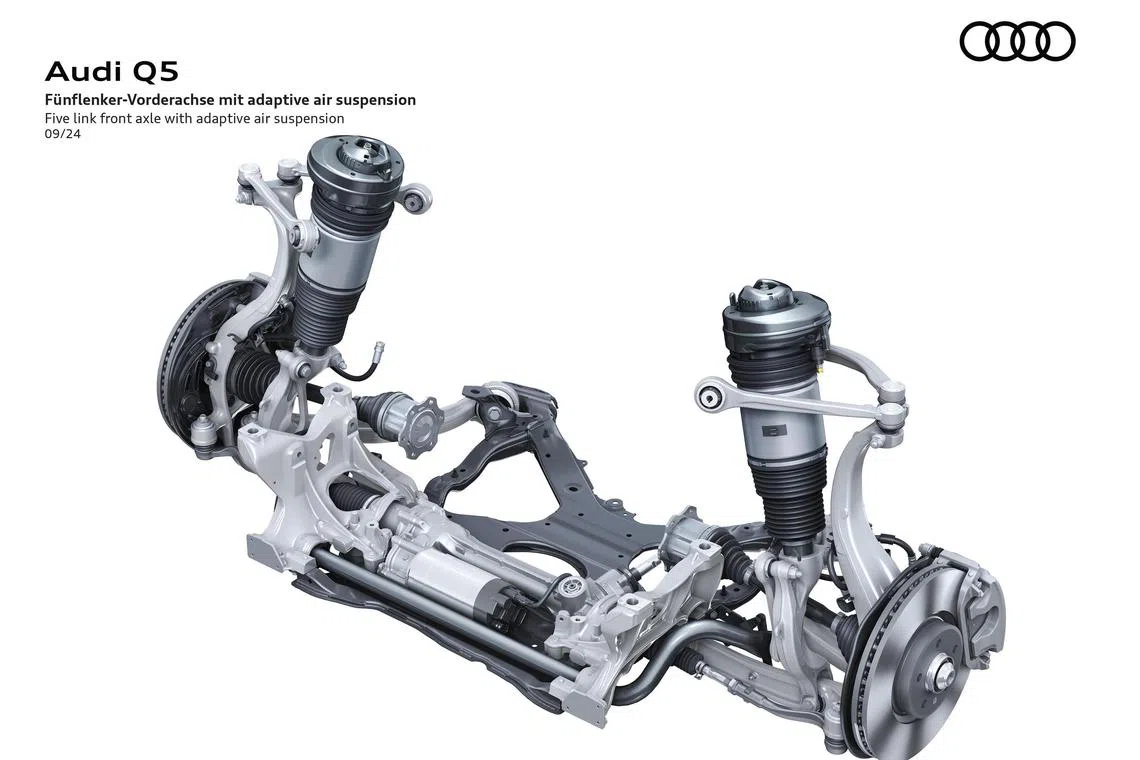

Chunky air bellows take the place of steel springs to keep the car levelled.

PHOTO: AUDI

Follow topic:

What does it mean when car manufacturers list “air suspension” in the data sheet? How different is this from a double-wishbone, multi-link or MacPherson strut system?

In many cases, when the term “air suspension” is stated in the specification sheet, there is rarely further elaboration on what it entails. This is likely because the carmaker wants to portray an image of sophistication, rather than explain the configuration of the suspension set-up.

Each wheel of an automobile is mounted on an assembly which consists of three main sub-units: a set of interconnecting levers or linkages, a spring and a damper. The design at the front is almost always different from that at the rear, primarily because the front wheels also steer the vehicle while handling 70 to 80 per cent of the braking force.

In an air suspension system, the conventional spring – usually made of steel – is substituted with a rubber bellow filled with pressurised air supplied by an on-board air compressor.

When it is “squeezed” under load, the rising internal pressure, due to decreasing internal volume, acts as a spring in absorbing road shock and maintaining the vehicle body level. Think about how the whole vehicle sits on rubber tyres filled with air, and it will come as no surprise that a pressurised rubber air plenum is capable of handling the impact loads over varying road surfaces.

Any double-wishbone, MacPherson strut or multi-link system can be incorporated with an air or pneumatic spring in place of a steel coil or torsion spring, while the other elements such as the linkages and hydraulic shock absorbers remain the same as a conventional steel spring set-up. It can be used on all four wheels or, in many cases, just the rear.

By varying the volume and pressure of the air within the pneumatic bellow, spring rate and ride height can be varied. When the boot is heavily laden with luggage, for example, the vehicle’s suspension control unit will activate the compressor to increase air pressure in the bellows, thereby reinstating original ride-height while also increasing spring stiffness to accommodate the increased weight. This is the biggest advantage of the air suspension: the ability to vary ride height and spring rate.

The term air suspension is also used on the more sophisticated set-up that incorporates variable rate dampers. Like the original Citroen hydro-pneumatic system, this type of design adds pressurised hydraulic fluid assisted by high-pressure nitrogen to handle the damping functions while the pneumatic bellows do the work of springs.

This version of suspension offers a very high level of handling and ride comfort, but is hugely expensive and hence found only in upmarket luxury cars.