Torque Shop: On-board Diagnostics used to uncover issue with car

Sign up now: Get ST's newsletters delivered to your inbox

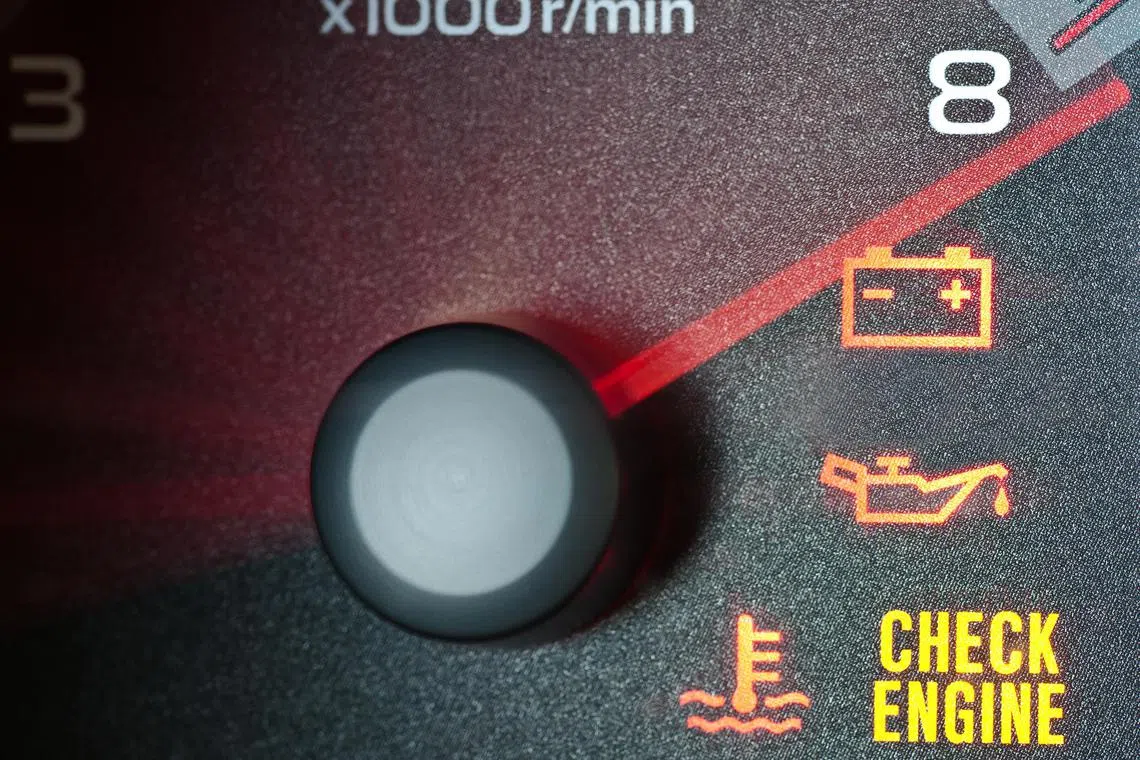

The "check engine" warning light could mean that there are malfunctions related to the engine's emissions.

PHOTO: NEWSPRESS

I drove my car into the dealership workshop to find out why I had a symbol light up in orange in my instrument cluster. The service adviser told me it was the “check engine” warning. He then mentioned that they would determine the problem with the OBD-2. What do the orange symbol and “OBD-2” mean?

That orange light on your instrument cluster indicates that there are malfunctions in some components in the engine. Most often, the problem is related to emissions.

Since 1988, all cars are required to have a system that continuously monitors the exhaust gas-related components in driving mode.

OBD is short for On-board Diagnostics. The primary purpose to legislate such a system was to raise an alarm via the check-engine light (also known as the malfunction indicator light or MIL), whenever the engine’s emission limits are exceeded.

The second generation, known as OBD-2, became mandatory for all cars from 1994 to include the monitoring of the component function, in addition to measuring emissions in the exhaust gases.

As an example, OBD-2 is capable of detecting a faulty sensor that would result in a false reading. The same on-board network also monitors and reports faults in other components of a vehicle, such as the transmission, lights or power windows.

Once a malfunction occurs, the on-board diagnostics will alert the driver via a digital message or, in the case of an engine fault, via the orange MIL. There could be a number of reasons for a fault, and the OBD-2 stores the information in memory as a fault code number.

At the workshop, an OBD scanner is plugged into a port under the dashboard to retrieve the stored fault code. Cross-referencing the Diagnostic Trouble Code (DTC) with the standard list will assist in identifying the defective component.

Sometimes, a little more investigation may be necessary to confirm that the component is indeed the root cause.

Once the workshop has fixed the problem, the scanner is used to reset the OBD and erase the record of the fault. It is possible to perform a reset without addressing the actual problem, but this is like swallowing painkillers to make chest pain go away.