Vietnam eyes first chipmaking plant, US officials warn of high costs

Sign up now: Get ST's newsletters delivered to your inbox

The Vietnamese government has said it wants its first fab by the end of this decade.

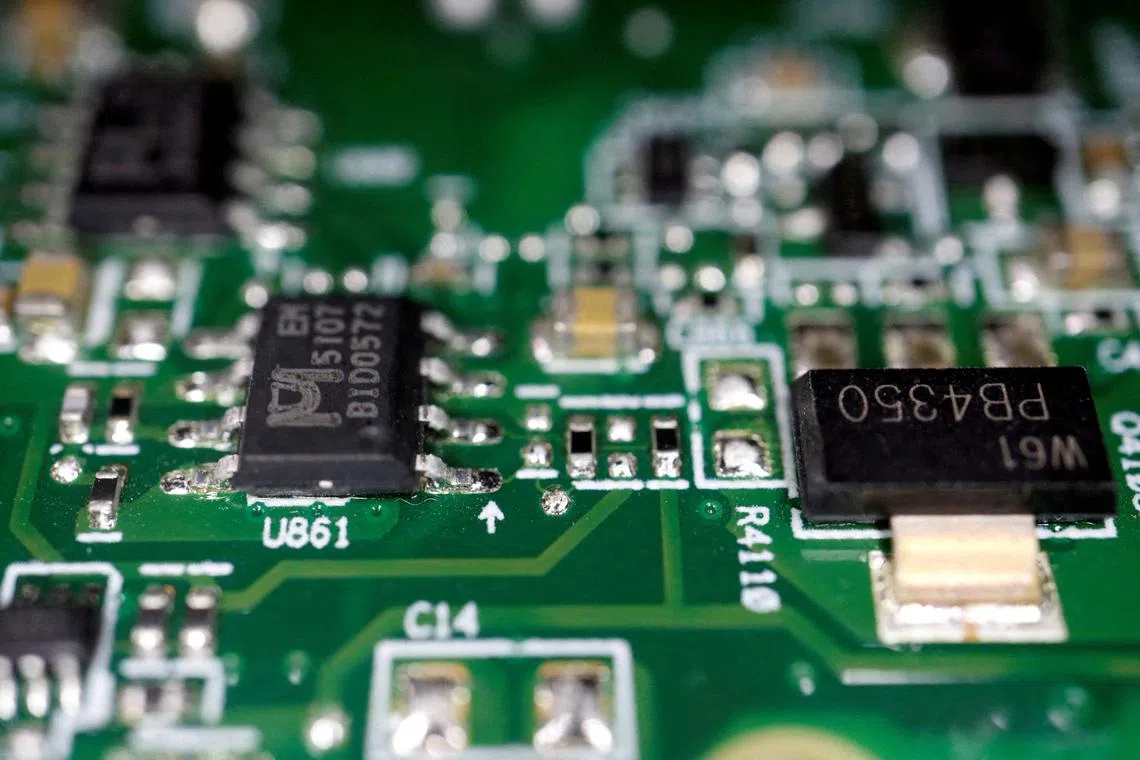

PHOTO: REUTERS

HANOI - Vietnam is holding talks with chipmakers with the aim of boosting investment in the country and possibly building its first semiconductor manufacturing plant, or fab, two business executives said, despite warnings from US industry officials about high costs.

The South-east Asian electronics manufacturing hub already hosts US giant Intel’s largest semiconductor packaging and testing plant worldwide and is home to several chip designing software firms. It is now working on a strategy to attract more semiconductor investment, including from foundries to manufacture chips.

Meetings with half a dozen US chip firms took place in recent weeks, including with fab operators, Mr Vu Tu Thanh, head of the Vietnam office of the US-Asean Business Council, told Reuters. He declined to identify the firms because talks were still at a preliminary stage.

A chip executive, who declined to be identified, said talks with potential investors have involved US contract manufacturer GlobalFoundries and Taiwan’s PSMC.

The aim was to build Vietnam’s first fab, most likely for less advanced chips used in cars or for telecoms applications, the executive added.

The meetings followed a historic upgrade of formal ties between Vietnam and the United States

GlobalFoundries attended a restricted business summit during the visit after an invitation from Mr Biden himself, the company said, but has since shown no immediate interest in investing in Vietnam, a person familiar with the matter said. “We do not comment on market rumours,” a GlobalFoundries spokesperson said when asked about subsequent contacts. PSMC did not reply to a request for comment.

Industry officials said meetings at this stage were mostly to test interest and discuss potential incentives and subsidies, including on power supplies, infrastructure and the availability of a trained workforce.

The Vietnamese government has said it wants its first fab by the end of this decade, and on Monday said chip companies would benefit from “the highest incentives available in Vietnam”.

It may also support local firms such as state-owned tech company Viettel to build fabs with imported equipment, Dr Hung Nguyen, senior programme manager on supply chains at RMIT University Vietnam, told Reuters.

US$50 billion bet

However, Mr Robert Li, vice-president of Synopsys, a leading US chip design firm with operations in Vietnam, urged the government to “think twice” before doling out subsidies to build fabs.

Speaking at the Vietnam Semiconductor Summit in Hanoi on Sunday, he said building a foundry could cost as much as US$50 billion (S$68 billion), and would entail competing on subsidies with China, the US, South Korea and the European Union, which have announced spending plans on chips between US$50 billion and US$150 billion each.

Mr John Neuffer, president of the US Semiconductor Industry Association, at the same conference recommended the government focus on chip sectors where Vietnam was already strong, such as assembling, packaging and testing. REUTERS