Singapore’s first energy positive industrial building opens in Kranji

Sign up now: Get ST's newsletters delivered to your inbox

The energy consumption of the building is kept to a minimum through numerous smart building management systems.

PHOTO: SAMWOH SMART HUB

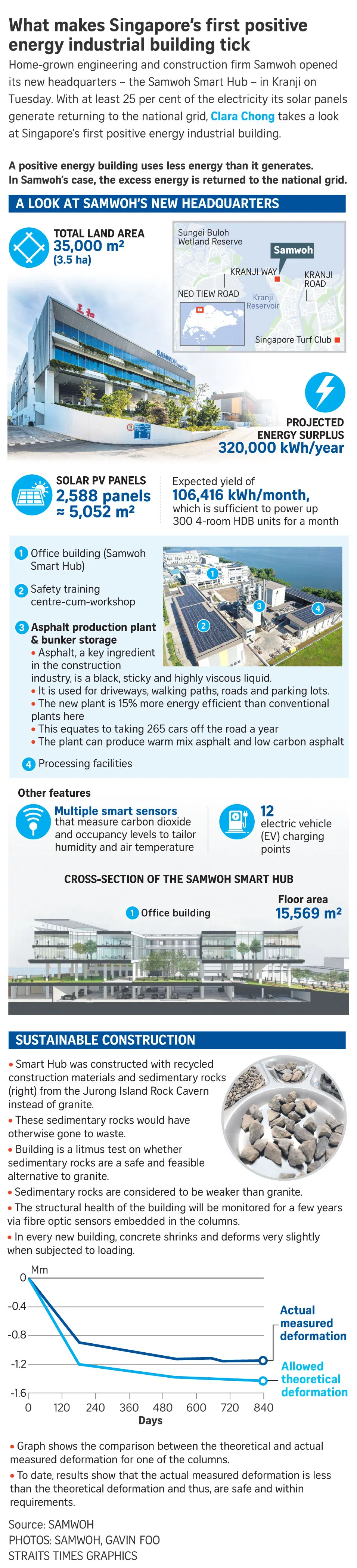

SINGAPORE - Home-grown engineering and construction firm Samwoh opened its new headquarters in Kranji on Tuesday, featuring the nation’s first positive-energy industrial building.

This means that the building generates more energy than it uses. At least 25 per cent of the electricity generated by the Samwoh Smart Hub’s 2,588 solar panels will be returned to the national grid.

It is among the few buildings in Singapore to attain the Building and Construction Authority’s Green Mark Platinum Positive Energy certification.

The energy consumption of the building is kept to a minimum through numerous smart building management systems, such as the extensive use of sensors to optimise the temperature and humidity inside the four-storey structure.

The hub has a floor area of 15,569 sq m and sits on a 35,000 sq m plot of land – about the size of five football fields – leased to Samwoh.

A more efficient asphalt production plant has also been built beside the hub. It is 15 per cent more energy-efficient than a conventional asphalt production plant – with the energy savings equivalent to taking 265 cars off roads annually.

Previously, Samwoh’s facilities were distributed over five plots of land around Singapore. The leases of three of them have since expired, with the leases of the remaining two plots expiring by 2025.

Deputy Prime Minister Heng Swee Keat was guest of honour at the opening of the Kranji headquarters, which consolidates all of Samwoh’s operations.

Noting the urgency of focusing on sustainability, Mr Heng said: “Much more needs to be done, especially in the built environment sector. Buildings account for around 40 per cent of global carbon emissions, of which around a third are attributable to building materials and construction.

“Samwoh’s focus on sustainability is most salient, as we seek to galvanise greater momentum for a more climate-friendly built environment industry.”

The company, which was established in 1975, said its Smart Hub is a push by the company to green the construction and civil engineering industry through innovative and novel means, as well as attract young talent to the sector.

For instance, the hub was constructed with various types of recycled construction materials, and a portion of the hub was made with sedimentary rock – traditionally not used for buildings – from the Jurong Rock Caverns instead of granite, which is imported into the Republic.

But sedimentary rocks are considered weaker than granite. They are formed on or near the earth’s surface, in contrast to metamorphic and igneous rocks formed deep within the planet. Granite is a type of igneous rock that is typically used as structural concrete in buildings.

At least 25 per cent of the electricity generated by the Samwoh Smart Hub’s 2,588 solar panels will be returned to the national grid.

PHOTO: SAMWOH

Into its third year of testing, the part of the building built with sedimentary rock acts as a litmus test to determine whether this material is a safe and feasible alternative to granite. The structural health of the building will be monitored for a few years via fibre optic sensors embedded in the columns.

So far, test results have shown that the building is structurally safe.

Housed within the Smart Hub is also the company’s new innovation centre, where cutting-edge research and development is being carried out. Some ongoing projects include the use of high-performance asphalt for aircraft pavements to resist heavy traffic loading and higher temperatures.

Asphalt is a sticky, black, highly viscous liquid that binds stone, sand and gravel. This mixture is eventually used in pavements, roads and highways.

On the difficulty in attracting younger talent, Samwoh chief executive Eric Soh said: “It has never been easy for an older, more traditional industry like ours to attract younger talent. But the construction of roads and expressways remains integral, though much of it may sound unglamorous or is unseen by the public.”

He said many of the stereotypes are not true. “The Smart Hub shows our focus towards sustainability, innovation and the use of digital tools to optimise processes,” Mr Soh said. “It is an exciting place, with a huge number of projects that our talented scientists and engineers can work on.”

The company is expanding its existing digital applications into a cloud-based tracking system so information and data can be analysed and viewed in real time and from anywhere, thereby increasing the efficiency of operations.

DPM Heng Swee Keat (second from left) with (from left) Samwoh’s head of sustainability and innovation department Kelvin Lee, CEO Eric Soh and COO Ho Nyok Yong at the company’s new headquarters in Kranji on Tuesday.

ST PHOTO: NG SOR LUAN

On the new amenities staff can now enjoy on Samwoh’s premises, Mr Heng said in his opening address: “Eric is also a fervent advocate of work-life balance and a healthy workforce. The Smart Hub, which is designed with the well-being of employees in mind, includes recreational spaces such as a gym and theatre.

“This must be a long-awaited homecoming for all staff.”

A notable past project by Samwoh was the overhaul of Changi Airport runways 1 and 2. Given the constant heavy impact of aircraft tyres, the runway pavement aged quickly. Samwoh removed and repaved the top layer of the runways with a polymer modified bitumen that is able to withstand higher temperatures.