Malaysia’s first home-grown EV to roll out of Tanjong Malim in drive towards auto hub goals

Sign up now: Get ST's newsletters delivered to your inbox

Malaysian Prime Minister Anwar Ibrahim (third from left) launched Proton’s first EV assembly plant in Tanjong Malim on Sept 4.

ST PHOTO: LU WEI HOONG

Follow topic:

- Proton launched its first EV assembly plant in Tanjong Malim, which is a step closer to positioning the area as an EV hub.

- PM Anwar wants Proton to produce cheaper EVs before the Asean summit in 2025, showcasing Malaysia's EV capabilities to global leaders.

- BYD is also establishing an assembly line by mid-2026 at the Automotive High Technology Valley in Tanjong Malim.

AI generated

TANJONG MALIM, Perak – Five gleaming white and dark silver cars took pride of place inside a factory in Perak, as workers awaited the arrival of VIPs, including Malaysian Prime Minister Anwar Ibrahim.

The cars were on display at Malaysia’s national carmaker Proton’s first electric vehicle (EV) assembly plant, which opened on Sept 4

That is where Proton’s first EV, the e.MAS 7, which has been manufactured in China since its launch in 2024, is expected to roll off local assembly lines later in September.

The first phase of Proton’s EV plant, which has an initial investment of RM47 million (S$14.4 million), can assemble 20,000 vehicles a year, with a maximum capacity of 45,000 units a year once the 2.25ha facility is fully operational.

The opening of the plant takes Malaysia a step closer to its goal of positioning Tanjong Malim as the country’s EV hub and attracting more industry players.

“The success of AHTV depends on how many carmakers are attracted (there) aside from Proton,” Mr Anthony Lim, senior editor of the country’s popular automotive website Paul Tan’s Automotive News, told The Straits Times.

In 2022, then Prime Minister Ismail Sabri Yaakob announced that Tanjong Malim had been earmarked as a hub for high-tech manufacturing and supply chains essential for advancing Malaysia’s new vehicle industries, including EVs.

In particular, AHTV will spearhead the country’s EV industry.

According to government plans, AHTV is expected to create 160,000 jobs across research and development, automotive-related vendors, and original equipment manufacturers (OEMs), generating an estimated economic value of RM32 billion by 2030.

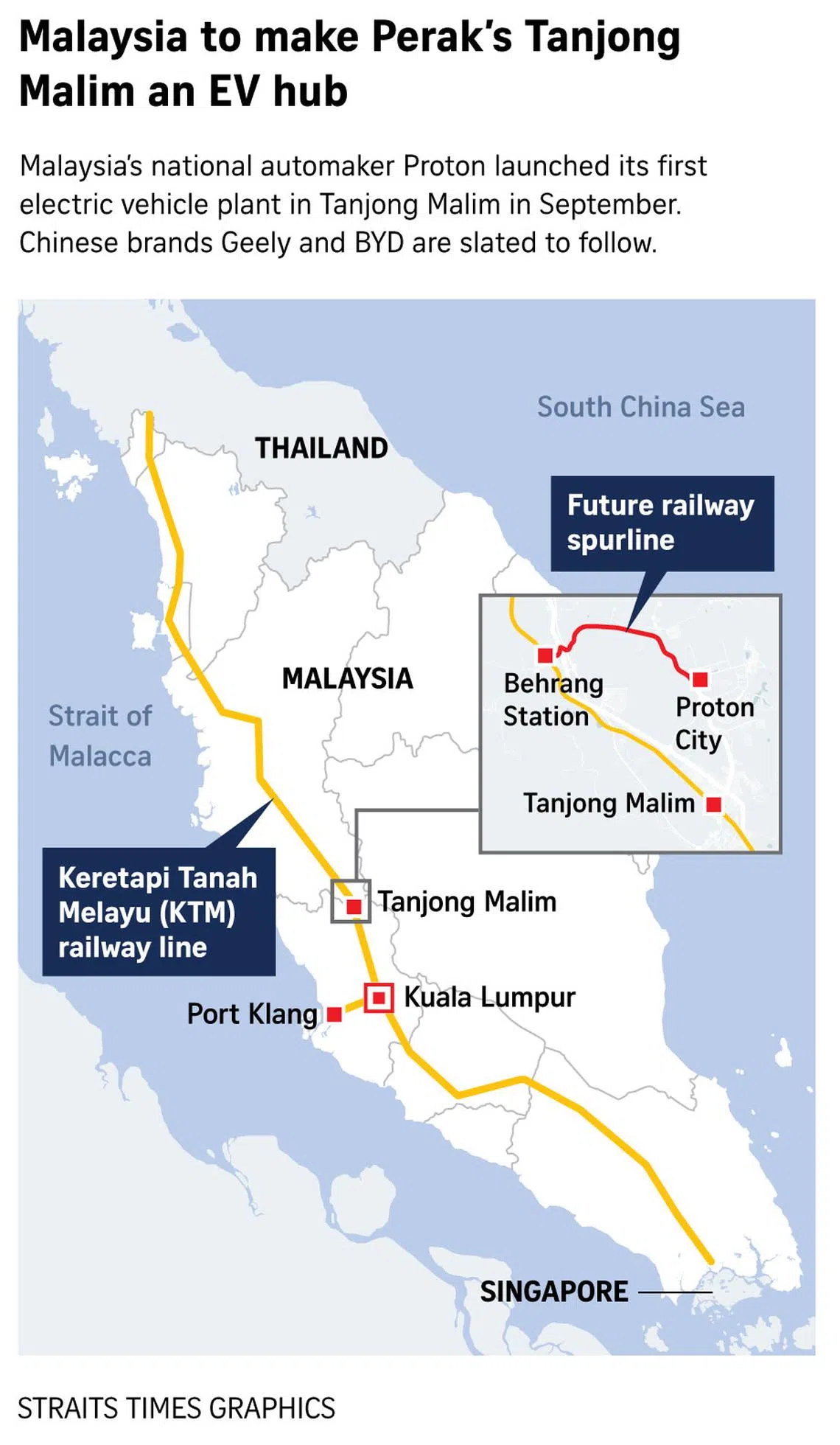

To support AHTV’s growth, a railway spur line is slated for construction to connect the hub with the Keretapi Tanah Melayu (KTM) network, enabling the transport of raw materials and completed EVs to Port Klang, the world’s 10th busiest port.

“I am waiting for the more competitive and cheaper Proton EV to be produced before the Asean summit in October 2025. We can showcase it to no less than 20 heads of states from Europe, Asia, Latin America and Africa. That’s why I tell Proton that it must produce the first EV before Asean,” said Datuk Seri Anwar at Proton’s launch.

EVs account for just under 3 per cent of total new vehicle registrations in 2024.

However, the EV market is growing, with 26,070 vehicles registered in the first seven months of 2025 – nearly matching the 28,048 for the whole of 2024.

And Chinese EV giant BYD is set to ride the momentum by establishing a new assembly line at AHTV, which is expected to begin operations by mid-2026, according to Perak executive councillor for industry and investment Loh Sze Yee.

“You’ll be surprised to know that all the necessary approvals were secured within a month, as BYD is considered a high-impact investment,” he told ST.

Mr Loh added that the federal government’s direction is to consolidate the entire automotive industry – along with all relevant approval agencies – under one roof at AHTV, to prevent competition or “cannibalism” between states in the same sector.

For Tanjong Malim MP Chang Lih Kang, the automotive ecosystem has been in place since the establishment of Proton City in 2003, which laid the groundwork for the development of AHTV.

“The Automotive High Technology Valley is already home to Proton’s main hub, complete with factories, suppliers, and a skilled workforce. Additionally, the Tanjong Malim exit on the North-South Expressway provides direct connectivity to Port Klang and other major markets,” Mr Chang, who is also the minister of science, technology and innovation, told ST.

At the launch of the Proton plant, Transport Minister Anthony Loke told reporters that a feasibility study is under way for the proposed railway connection from AHTV to the Behrang KTM Station 10 km away.

The project is estimated to cost between RM200 million and RM250 million.

Once connected to the KTM mainline, the proposed connection will provide access to the East Coast Rail Link and Port Klang, Mr Loke told reporters.

Proton, the first EV maker at AHTV, is majority owned by Malaysian conglomerate DRB-Hicom, with the remaining 49.9 per cent stake held by China’s Zhejiang Geely Holding Group.

The opening of the Proton plant takes Malaysia a step closer to its goal of positioning Tanjong Malim as the country’s EV hub and attracting more industry players.

ST PHOTO: LU WEI HOONG

At the launch, DRB-Hicom group managing director Syed Faisal Albar Syed A. R. Albar hailed Proton’s e.MAS 7 car as the most popular EV model in Malaysia.

“Nearly 5,000 units of the e.MAS 7 were sold domestically and internationally in the first seven months of 2025. We will soon begin production of the second variant, the e.MAS 5, which echoes the government’s call for affordable electric vehicles,” said Tan Sri Syed Faisal Albar.

The e.MAS 7 sells at RM105,800 for its Prime model and RM119,800 for its Premium model. The price of e.MAS 5, an entry-level option, has yet to be released.

The first phase of Proton’s EV plant can assemble 20,000 vehicles annually.

ST PHOTO: LU WEI HOONG

By 2027, Proton will relocate all production to AHTV from its Shah Alam plant in Selangor to consolidate operations, said Mr Lim of Paul Tan’s Automotive News.

“The new EV plant fits into that streamlined approach by integrating all supply chains,” he said.

At the launch, Mr Anwar expressed his appreciation to Beijing for facilitating the technology transfer to help nurture Malaysia’s automotive engineering talent and said the new facility reflected the close collaboration between the two countries.

He also called upon Geely to ramp up its investments in the auto hub.

“We want... Geely to use this opportunity to establish not only a factory to produce cars but also a centre of excellence for training and education,” he said.

Thirty Proton staff members have been trained to support the production of Malaysia’s first locally assembled EV.

Among them is operator Mohd Alif Daniel Mohd Nazari, 23, who was inspecting the e.MAS 7 ahead of Mr Anwar’s arrival.

“All of us EV operators are new. We’ve been working here since June. Nineteen of us underwent further training in China before starting work here,” he said.