Clearing the air: Innovative Japanese company eyes CO2 capture revolution to fight climate change

Sign up now: Get insights on Asia's fast-moving developments

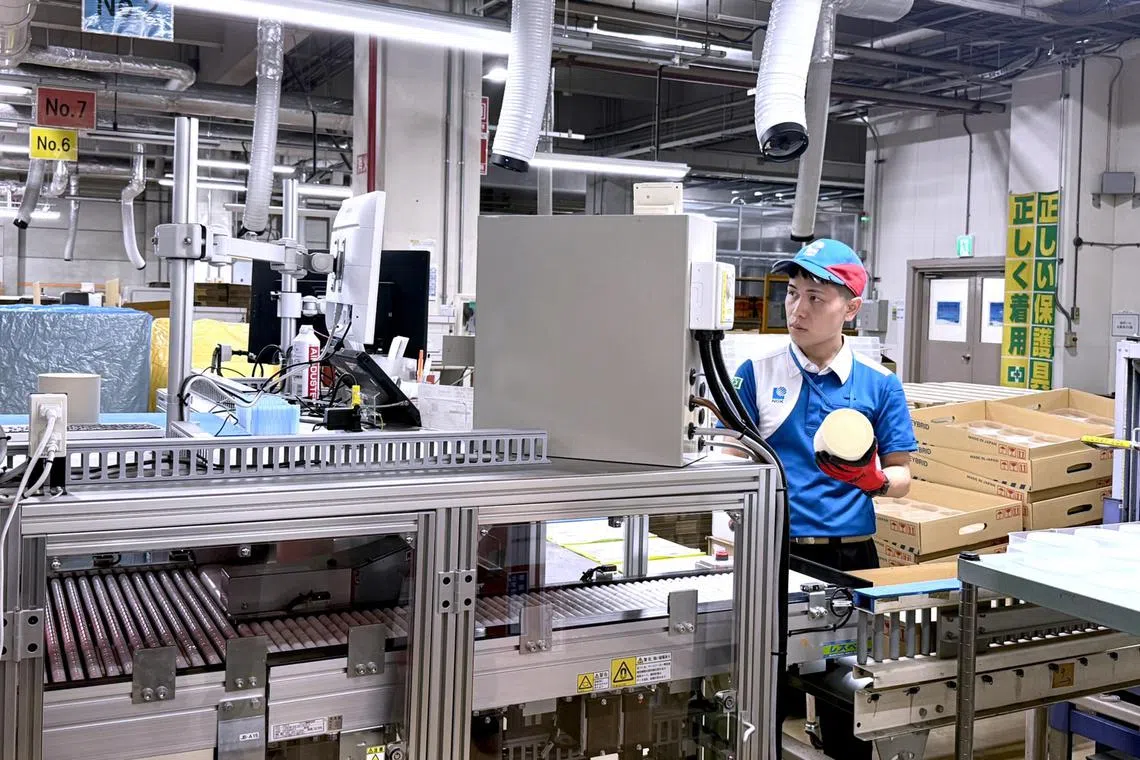

NGK Insulators’ facility in Nagoya. NGK Insulators believes its technology can be adapted to capture carbon dioxide from the air.

ST PHOTO: WALTER SIM

Follow topic:

NAGOYA – As the world accelerates away from petrol vehicles, the global leader in ceramic components for catalytic converters in car exhaust systems is also making a significant pivot.

Nagoya-based NGK Insulators believes its patented technology – a honeycomb structure that is coated with the catalyst that neutralises toxic pollutants in vehicle exhaust – can be adapted to capture carbon dioxide (CO2) directly from the atmosphere.

This process, known as direct air capture (DAC), has been lauded as a promising method to extract the greenhouse gas from the air to fight global warming.

Its function has been likened to that of a natural forest.

DAC technology captures CO2 from ambient air, rather than at points of emission like factories and power plants, where the gas is typically separated from flue gases using chemical solvents and then reused commercially.

Greenhouse gases, chiefly CO2 from burning fossil fuels and deforestation, are heating up the planet and driving more extreme weather, such as heatwaves and more powerful storms.

Technologies that can remove CO2 from the air are attracting growing investor interest, but high costs remain an impediment.

This challenge stems from the low concentration of CO2 in the air, at merely 0.04 per cent, thus requiring significant energy to channel air towards DAC facilities for efficient capture, explained Dr Hidetaka Yamada of Kanazawa University’s Frontier Science and Social Co-creation Initiative.

“Simply put, it takes extreme effort to collect something that is comparatively rare,” he said, noting that it can cost up to US$1,000 (S$1,280) to capture one tonne of CO2. The industry target is to lower this price to US$100.

Still, the world requires all available technologies in its arsenal to combat climate change, added Dr Yamada, who is also in the Japanese government’s DAC working group that was formed in 2024 with an eye on “strengthening industrial competitiveness”.

Direct captured CO2 can be stored underground, or chemically converted into products such as synthetic fuels, mineralised carbonates, or building materials like concrete.

Globally, there are an estimated 150 DAC companies with facilities already in operation in countries including the US and Iceland.

Prominent advocates include Microsoft, which has committed to buying 500,000 tonnes of DAC credits over six years.

An employee of NGK Insulators demonstrating how the company’s patented technology can be used to remove carbon dioxide from the air.

ST PHOTO: WALTER SIM

But the technology remains rare in Asia, even as companies like Japanese shipping giant Mitsui OSK Lines have committed to buying at least 50,000 tonnes (or US$25 million) of CO2 removal credits by 2030.

A DAC machine that deploys these honeycomb structures at scale could significantly increase the amount of CO2 captured compared with current methods, NGK said.

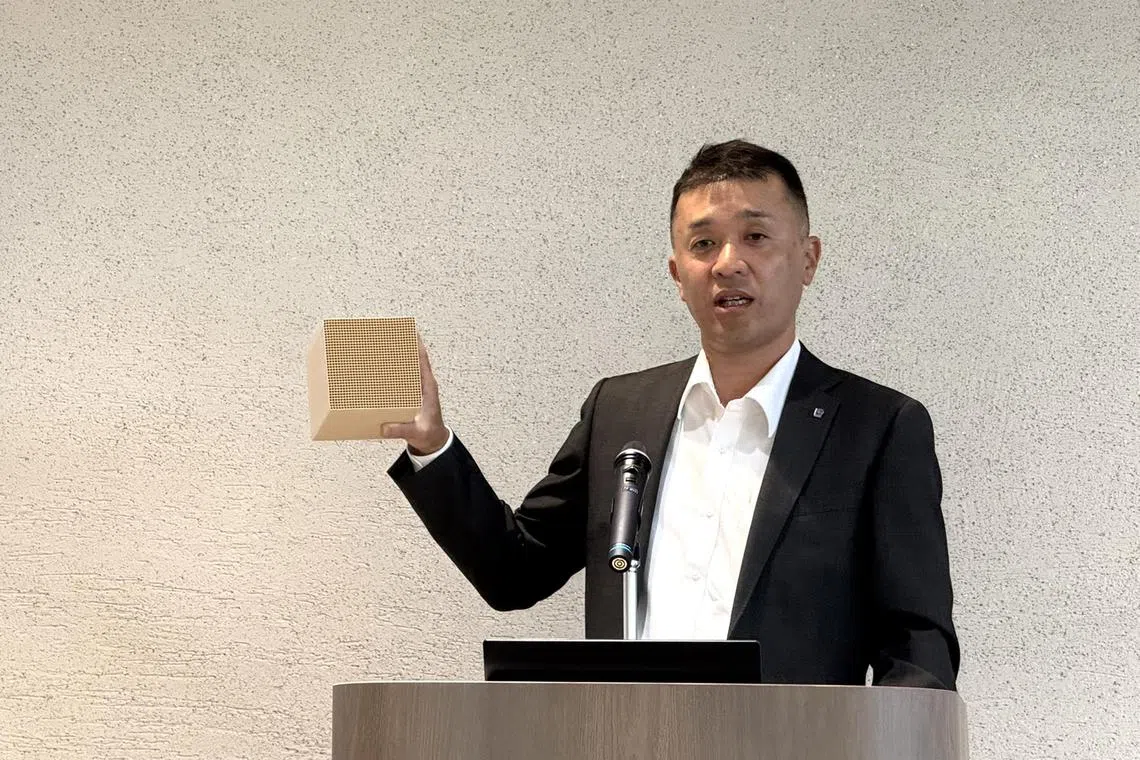

It is crucial to adopt technology that can efficiently channel small amounts of CO2, within large volumes of air, into contact with absorbents, said Mr Masataka Yamashita of NGK’s Environment Business Group, at a media briefing and demonstration on Sept 1.

A piece of NGK’s honeycomb substrate small enough to be held in one hand has an internal surface area equivalent to that of two football pitches, and allows air to flow smoothly through it, he said.

Unlike existing pellet-type substrates used in DAC, coating the honeycomb structure with a material like polyethyleneimine – which chemically binds CO2 – can significantly improve the rate of carbon capture and reduce costs, Mr Yamashita added.

NGK is now conducting field tests, with a goal of commercialising the technology by 2030, he said.

The company has the capacity to mass-produce DAC honeycombs at its 11 factories across eight countries, including the US, China, Indonesia and Poland.

NGK has not shared price points for its technology.

Mr Masataka Yamashita of NGK’s Environment Business Group said coating the honeycomb structure with a material like polyethyleneimine can significantly improve the rate of carbon capture and reduce costs.

ST PHOTO: WALTER SIM

Corporate Japan is increasingly recognising the risks of climate change.

NGK is a member of the Japan Climate Leaders’ Partnership (JCLP), a coalition of 229 businesses striving for a low-carbon society amid concerns that temperature records are being shattered every year.

In 2025, Japan sweltered through its hottest summer on record

Scientists blame human-induced climate change for the heatwave conditions.

With climate change referred to as a “silent crisis”, Japan has taken stronger steps by imposing criminal penalties on businesses that fail to take adequate steps to protect their employees from heatstroke.

However, public awareness has lagged, with the Japanese media rarely drawing the link between extreme heat and climate change over fears that doing so would alienate audiences, said TV Tokyo weather caster Akiko Ishigure.

She was speaking at a JCLP event on Aug 8, which the coalition has designated as an annual “day to end excessively hot summers” by addressing the awareness gap and leveraging Japan’s cultural enthusiasm for commemorative dates.

JCLP executive Yusuke Matsuo said: “While many politicians may be concerned about climate change, they cannot take further steps without the support of voters. We want to work together with the government and citizens to overcome this challenge by conveying its severity.”

Mr Nobuyuki Miyaji, an executive officer of Seven & i Holdings – the operator of 7-Eleven convenience stores and a JCLP member company – added: “It is essential to raise awareness among our customers. We want them to consider global warming as a personal issue. This can lead to behavioural change and, eventually, transform our society.”

The Japanese Ministry of Economy, Trade and Industry (Meti) said Japan can achieve its goal of becoming carbon-neutral by 2050 only if it can “remove enough carbon dioxide to offset residual emissions from hard-to-abate industrial sectors despite ongoing efforts to slash emissions”.

Hard-to-abate sectors include steel and cement-making and refining.

Forecasts by the United Nations’ Intergovernmental Panel on Climate Change (IPCC) indicate that Japan will likely emit between 50 million and 240 million tonnes of residual emissions annually from 2050.

The International Energy Agency (IEA) also projects that global annual CO2 capture must reach six billion tonnes by 2050, with DAC accounting for one-fifth of that total, to achieve the climate targets of the UN’s Paris Agreement.

Meti aims for Japan to develop domestic technologies for CO2 export overseas, given that Japan’s mountainous terrain is not conducive for large-scale underground storage of the greenhouse gas.

It has identified potential international partners in countries including Indonesia, Malaysia and Australia, which have the right geological conditions, such as deep saline aquifers a kilometre or more underground, into which the CO2 can be pumped for long-term storage. At least, that is the hope.

“Many Japanese companies possess particularly advanced technologies in materials, such as catalysts and substrates, and in plant design and construction,” a Meti report said.

It added: “Domestic firms can therefore participate significantly in the DAC supply chain.”

NGK’s efforts, meanwhile, have been recognised by the government’s DAC working group.

Its innovation won the stamp of approval of former IEA executive director Nobuo Tanaka, who attended the media briefing on Sept 1.

He told The Straits Times: “Even if this technology cannot be readily deployed in Japan but overseas where DAC storage is possible, this could be a very interesting company that could create a DAC revolution.”