China touts success of its first home-grown nuclear reactor

Sign up now: Get insights on Asia's fast-moving developments

A control room at a CNNC Zhangzhou New Energy office to monitor construction progress and manage on-site safety.

ST PHOTO: LIM MIN ZHANG

FUJIAN – In a coastal province known for fishery and trade, a grey, dome-topped, reinforced concrete building is the repository of China’s growing ambitions to export nuclear power.

The building – strong enough to withstand a commercial plane crash – houses the Hualong One, China’s first home-grown, third-generation nuclear reactor, which came online in March 2022.

Known as Unit 5 of the Fuqing Nuclear Power Plant, it is one of two reactors – Units 5 and 6 – that form the demonstration project.

China has joined the US, Japan, France, Russia and South Korea as countries that have developed commercial third-generation reactors since such designs for this clean form of energy began to be deployed in the 1990s. The US and Russia are leading exporters of nuclear reactors.

Third-generation reactors have better safety features, shorter construction times and longer lifespans – typically 60 years – than their earlier counterparts. Second- and third-generation reactors form the majority of nuclear reactors in operation today.

While the Hualong One is not seen as a technological game changer, and building costs have yet to come down significantly, analysts said it could make for a competitive export to developing countries, especially if financing is included.

But geopolitics will still figure strongly in potential customers’ considerations, they added. The US has accused China of using reactor sales as a way of fostering energy dependence on Beijing, and has discouraged other countries from these deals.

Still, American-led tech restrictions on China, such as on cutting-edge semiconductors, are often viewed by China as attempts to hold back its development.

On a media trip to Fujian organised by the All-China Journalists Association in late October, Chinese officials spoke of the Hualong One’s reliability, safety record and China’s construction prowess as its main advantages in the international market.

Units 5 and 6 at Fuqing Nuclear Power Plant in Fujian province, the site of China’s Hualong One demonstration project.

ST PHOTO: LIM MIN ZHANG

The Hualong One is jointly developed by state-owned giants China National Nuclear Corporation (CNNC) and China General Nuclear Power Group. The demonstration project at Fuqing city was built relatively quickly, in 69 months, starting in 2015. The target for subsequent units is 60 months, or five years.

The Hualong One is the culmination of more than 30 years of the country’s experience with nuclear power, since China’s first – and now largest – nuclear power plant was built in Qinshan in Zhejiang province in 1985. That plant was designed and built by China, although with foreign components involved.

The third-generation reactor is a source of pride for China. Senior nuclear simulation instructor Cao Yuhua vividly remembers the moment she received a WeChat message on March 25, 2022, that Unit 5 had turned operational. She is Hualong One’s first woman operator, who joined the project in 2014.

“I believe that on that day, everyone who was part of the Hualong One project would have felt gratitude and pride,” she told reporters on Oct 23 during the media tour.

Nuclear energy is regarded as a key source of clean energy for China, even as nuclear accounted for just 4.8 per cent of its total power generation in 2023. Rapid construction over the last decade means that China now has 102 nuclear reactors, with 56 in operation and 46 under construction.

Of the 102, 30 are Hualong One units. Four are in operation – two at Fuqing and two in Guangxi autonomous region – and 26 are under construction.

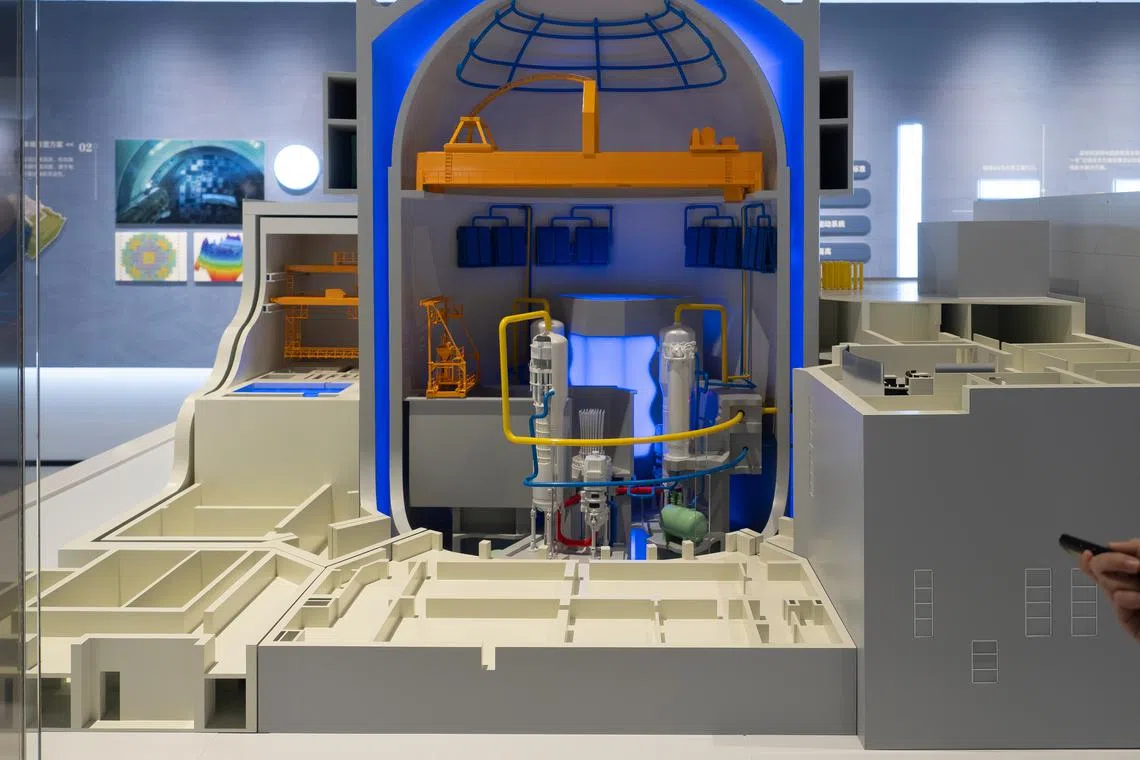

A model of the interior of the Hualong One nuclear reactor in a museum showcasing its technology and contributions to China’s nuclear programme, in Zhengzhou, Fujian province.

ST PHOTO: LIM MIN ZHANG

Hualong Nuclear Power Technology, set up in 2016 to promote the Hualong One overseas, said the Fuqing project has supplied more than 300 billion kWh of clean electricity domestically, equivalent to saving 85 million tonnes of coal.

But overseas, China’s track record on the Hualong One is modest. Pakistan, a close Chinese partner, is the first, and so far only, importer of the Hualong One, with two units that began commercial operation in 2021 and 2022.

A 2022 agreement with Argentina to build the Hualong One there has stalled. Other countries that were reportedly considering the reactor, such as Saudi Arabia, have not made definite commitments.

Data from 2022 showed that leading exporters Russia, the US and Sweden each commanded more than 16 per cent of the nuclear reactor market, while China had a less than 2 per cent share. This includes reactors, fuel elements and other machinery.

Fears over nuclear safety in the 2010s, fuelled by the Fukushima nuclear disaster in Japan,

Mr David Fishman, a senior manager specialising in the Chinese power sector at the Lantau Group economic consultancy, said that up until the 2010s, many countries had been planning to build a large variety of second- and third-generation reactors, including China.

But the catastrophic accident in Japan, following an earthquake and tsunami in 2011, caused China to pause approvals for new nuclear power plants for more than three years, until 2014.

The Fukushima accident also prompted China to cancel all plans to build any more second-generation reactors in favour exclusively of third-generation reactors, which have better safety performance.

The Hualong One’s design – like other later third-generation designs – is meant to be “Fukushima-proof” in preventing nuclear leakages.

Mr Fishman said the decision to build only third-generation reactors meant that China’s only options were to build imported AP1000s from American company Westinghouse or import EPRs from France’s Areva.

“Later, starting around 2016, the trade war and geopolitical tensions underlined the importance of developing an indigenous reactor tech,” he added, referring to the US-China rivalry.

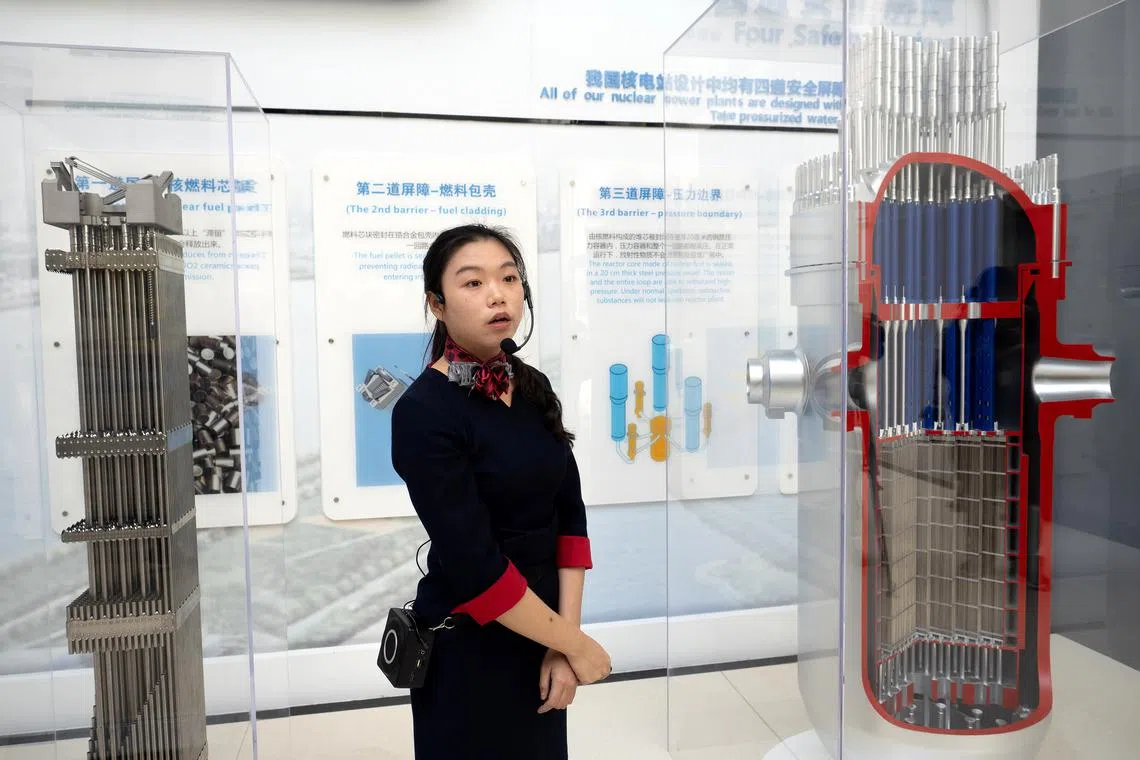

A staff member giving a tour of Hualong One technology next to models of the interior of the nuclear reactor to show its safety features.

ST PHOTO: LIM MIN ZHANG

China said at least 88 per cent of the Hualong One is made domestically, including core technology such as steam generators and pressure vessels. This is expected to increase to 95 per cent when mass production starts.

Operations shift manager at Fuqing Nuclear Power Plant Li Zonglin told reporters that China has achieved, and even surpassed, international safety standards for third-generation reactors, such as core damage frequency, which measures the likelihood of a serious accident damaging a nuclear core.

But less was said about its cost. Officials were not able to say how much it takes to build a Hualong One, but media reports have put the figure at 20 billion yuan (S$3.7 billion) for a domestic one and US$8 billion (S$10.6 billion) for the Argentina plant.

Dr Victor Nian, founding co-chairman of the Centre for Strategic Energy and Resources, a Singapore-based independent think-tank, said domestic production will help reduce costs, given the competitiveness of Chinese heavy industry, with its decades of experience and track record.

“It won’t come as a surprise that the Hualong One will be offered at a lower price compared with international rivals, perhaps with the potential exception of South Korea,” he said.

Mr Fishman said the Hualong One could be competitive anywhere, and not just among countries of China’s Belt and Road Initiative. The 11-year-old global infrastructure building project has extended to vast regions of the developing world, from Africa to Latin America to Central Asia.

“But I think it’s fair to say that China is going to see the most success with its ambitions for nuclear exports in places that need more of a turnkey package, which includes financing, which (points to more of) the developing world,” he said.

“The ability of the US or France to exert diplomatic or economic pressure to not work with China will likely be more effective in places that have stronger financing options themselves, whereas their lobbying efforts will probably be weaker where China’s package offering is attractive.”

Dr Philip Andrews-Speed, a senior research fellow at the Oxford Institute for Energy Studies, said the Hualong One has received the United Kingdom’s Generic Design Approval, showing that it is suitable for deployment there. This could be useful for other countries that may lack the capacity to carry out such assessments.

But the drawback for countries that lack their own capacity to design and build reactors is that hosting a Hualong One ties the country to China for many decades – through planning, construction, operation and decommissioning.

“Political leaders may decide that this is not something they want for the country,” said Dr Andrews-Speed, who has written extensively on China’s nuclear capabilities.

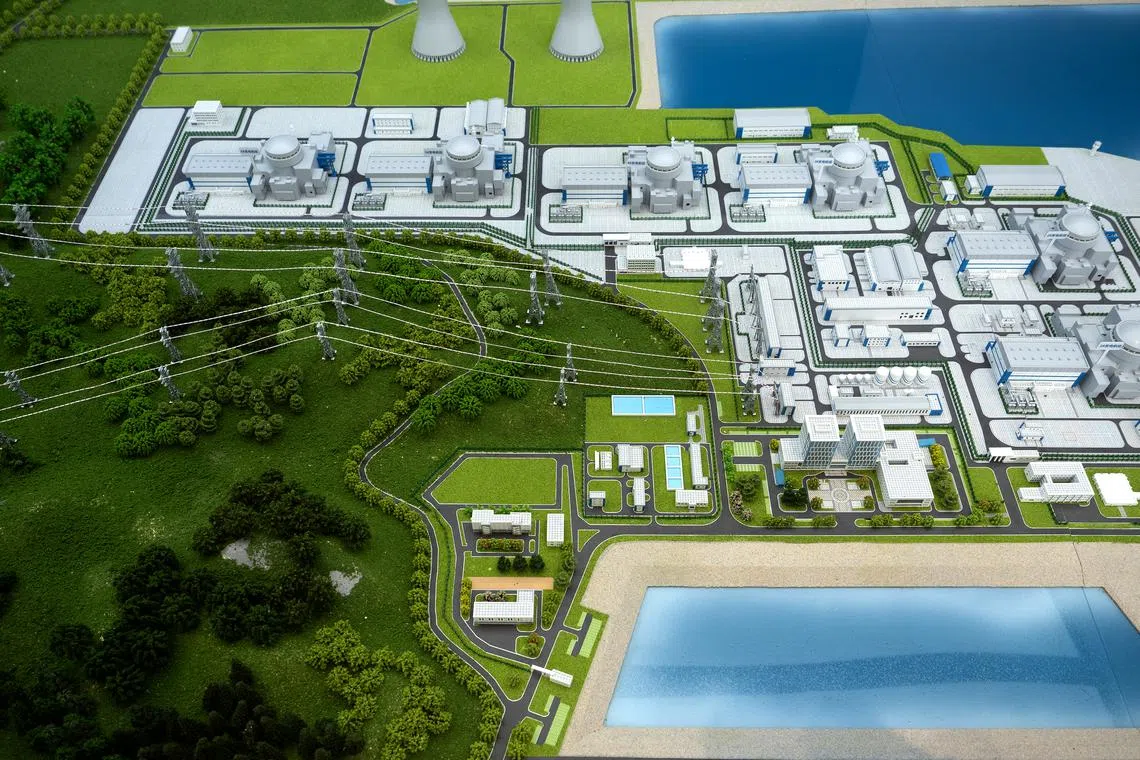

Farther south along China’s east coast, building continues apace at Zhangzhou Nuclear Power Plant, also in Fujian. The first of six units there is expected to start generating power by the end of 2024, after construction began in October 2019.

A model of the Zhengzhou Nuclear Power Plant, with six units of Hualong One reactors being planned.

ST PHOTO: LIM MIN ZHANG

On cost competitiveness, Mr Li Bin, media spokesman for CNNC Zhangzhou New Energy, which owns the power plant, said: “In the earlier stages, our costs might be high, but that will drop as we continue to build.”

He added that many foreign third-generation reactors have been built in China with Chinese involvement, such as the Sanmen Power Plant in Zhejiang province, which was the first to use Westinghouse’s AP1000. The European EPR’s first operational units are at Taishan Power Plant in Guangdong province. Both were connected to the grid in 2018.

“This shows that our engineering and delivery capabilities are strong. The 60-month construction target (for the Hualong One) is competitive, and can still be reduced even further,” he said.